oem 6 in u bolts

Oct . 16, 2024 04:01 Back to list

oem 6 in u bolts

Understanding OEM 206 in U-Bolts Significance and Applications

U-bolts are commonly used fastening devices with a U-shaped design, widely applied in various industries, especially in automotive, construction, and agricultural sectors. Among these, the OEM 206 U-bolt is a specific standard that has gained attention due to its particular dimensions and load-bearing capabilities.

OEM, or Original Equipment Manufacturer, refers to products that are made by a company for use in another company's finished products. The use of OEM parts ensures compatibility and reliability, which is especially vital in critical applications. The OEM 206 standard in U-bolts signifies a specific design and structural integrity, ensuring that these fasteners can perform effectively under the conditions they are intended for.

Design and Specifications of OEM 206 U-Bolts

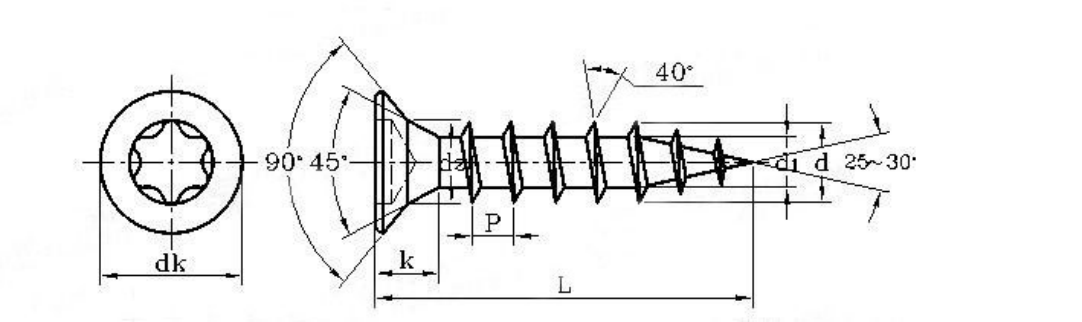

The design of an OEM 206 U-bolt consists of a U-shaped rod with threads on both ends. The length, diameter, and thread specifications align with industry standards, making it suitable for various mounting applications. The typical materials used in the manufacture of these U-bolts include high-strength steel or stainless steel, which provide excellent durability and resistance to corrosion.

A key specification of OEM 206 U-bolts involves their load-bearing capacity. This is crucial in applications where heavy loads are involved, such as in agricultural implements that require high-strength fastening solutions to secure frames and components. The standardized dimensions ensure that they can be easily replaced without needing modifications, enhancing maintenance efficiency.

Applications of OEM 206 U-Bolts

oem 6 in u bolts

OEM 206 U-bolts are versatile and find applications across different industries. In the automotive sector, they are often used in leaf spring assemblies and axle mounts. The automotive industry benefits significantly from using OEM parts, as they provide a guarantee of quality and performance which is essential for safety and reliability.

In the construction industry, these U-bolts are used to secure structures like scaffolding or support beams, ensuring stability and strength. They are also popular in the manufacturing of trailers and other heavy-duty transport equipment, where robust fastening solutions are critical to maintaining performance under load.

Advantages of Using OEM 206 U-Bolts

One of the primary advantages of using OEM 206 U-bolts is their designed-to-fit specification. When a business opts for OEM parts, it minimizes the risks associated with using generic or off-brand alternatives, which may not meet the quality and safety standards necessary for critical applications.

Furthermore, using OEM U-bolts aids in maintaining warranty coverage on vehicles and equipment, an essential factor for many businesses. The reliability of OEM products also contributes to reduced maintenance costs over time, as these parts are engineered to last longer, endure harsh conditions, and perform efficiently.

Conclusion

In conclusion, the OEM 206 U-bolt is a vital component in many industries due to its specific design, load-bearing capabilities, and reliability. Understanding its importance helps businesses make informed decisions regarding fastening solutions, ensuring safety and durability across various applications. As industries continue to evolve, the demand for high-quality, standardized components like the OEM 206 U-bolt will remain integral to maintaining operational efficiency and safety.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025