OEM underground wire connectors

Jun . 16, 2024 10:47 Back to list

OEM underground wire connectors

Understanding the Significance of OEM Underground Wire Nuts

In the intricate world of electrical installations and underground wiring systems, Original Equipment Manufacturer (OEM) underground wire nuts play an indispensable role. These small, yet critical components serve as the backbone of reliable and efficient electrical connections, ensuring safety and longevity in various underground applications.

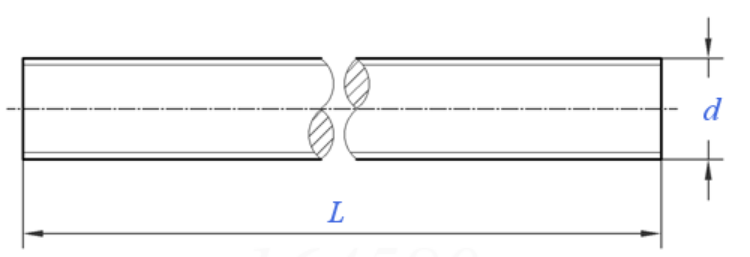

Wire nuts, also known as wire connectors or wire ferrules, are used to join two or more electrical wires together, creating a secure and insulated connection. When it comes to underground wiring, the stakes are significantly higher due to the exposure to moisture, soil corrosion, and potential mechanical stress. This is where OEM underground wire nuts prove their worth.

OEM, or Original Equipment Manufacturer, refers to a company that produces parts or equipment specifically designed for a particular manufacturer's product. In the context of underground wire nuts, this means they are tailor-made to withstand the harsh conditions prevalent in underground installations. They are engineered with materials and specifications that ensure optimal performance and durability under ground.

The primary advantage of using OEM underground wire nuts is their superior resistance to water ingress and corrosion. Made from high-quality materials such as nylon or thermoplastic, these connectors have excellent insulating properties, preventing electrical leakage and short circuits. Their robust design also safeguards against mechanical damage from soil movement or external pressure.

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement oem underground wire nuts. This enhances the stability and reliability of the electrical connection, reducing the risk of failures or maintenance issues.

Another key aspect is their ease of use. Despite their specialized nature, OEM underground wire nuts typically follow standard wire nut application procedures, allowing for quick and efficient installation by electricians. Their compact size also enables them to fit into tight spaces within underground conduits or cable ducts.

Furthermore, these wire nuts comply with industry standards and regulations, ensuring compliance and safety in any project. They undergo rigorous testing to meet stringent quality control measures, providing peace of mind to both installers and end-users.

In conclusion, the significance of OEM underground wire nuts lies in their ability to provide secure, durable, and reliable connections in challenging environments. They are an essential part of any underground electrical system, safeguarding not only the functionality but also the safety of the infrastructure. By choosing the right OEM underground wire nuts, engineers and contractors can ensure that their projects stand the test of time and the rigors of the earth beneath us.

oem underground wire nuts. This enhances the stability and reliability of the electrical connection, reducing the risk of failures or maintenance issues.

Another key aspect is their ease of use. Despite their specialized nature, OEM underground wire nuts typically follow standard wire nut application procedures, allowing for quick and efficient installation by electricians. Their compact size also enables them to fit into tight spaces within underground conduits or cable ducts.

Furthermore, these wire nuts comply with industry standards and regulations, ensuring compliance and safety in any project. They undergo rigorous testing to meet stringent quality control measures, providing peace of mind to both installers and end-users.

In conclusion, the significance of OEM underground wire nuts lies in their ability to provide secure, durable, and reliable connections in challenging environments. They are an essential part of any underground electrical system, safeguarding not only the functionality but also the safety of the infrastructure. By choosing the right OEM underground wire nuts, engineers and contractors can ensure that their projects stand the test of time and the rigors of the earth beneath us.

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement

Moreover, OEM underground wire nuts often come with additional features like strain relief, which secures the wire and prevents it from being pulled loose due to vibrations or movement oem underground wire nuts. This enhances the stability and reliability of the electrical connection, reducing the risk of failures or maintenance issues.

Another key aspect is their ease of use. Despite their specialized nature, OEM underground wire nuts typically follow standard wire nut application procedures, allowing for quick and efficient installation by electricians. Their compact size also enables them to fit into tight spaces within underground conduits or cable ducts.

Furthermore, these wire nuts comply with industry standards and regulations, ensuring compliance and safety in any project. They undergo rigorous testing to meet stringent quality control measures, providing peace of mind to both installers and end-users.

In conclusion, the significance of OEM underground wire nuts lies in their ability to provide secure, durable, and reliable connections in challenging environments. They are an essential part of any underground electrical system, safeguarding not only the functionality but also the safety of the infrastructure. By choosing the right OEM underground wire nuts, engineers and contractors can ensure that their projects stand the test of time and the rigors of the earth beneath us.

oem underground wire nuts. This enhances the stability and reliability of the electrical connection, reducing the risk of failures or maintenance issues.

Another key aspect is their ease of use. Despite their specialized nature, OEM underground wire nuts typically follow standard wire nut application procedures, allowing for quick and efficient installation by electricians. Their compact size also enables them to fit into tight spaces within underground conduits or cable ducts.

Furthermore, these wire nuts comply with industry standards and regulations, ensuring compliance and safety in any project. They undergo rigorous testing to meet stringent quality control measures, providing peace of mind to both installers and end-users.

In conclusion, the significance of OEM underground wire nuts lies in their ability to provide secure, durable, and reliable connections in challenging environments. They are an essential part of any underground electrical system, safeguarding not only the functionality but also the safety of the infrastructure. By choosing the right OEM underground wire nuts, engineers and contractors can ensure that their projects stand the test of time and the rigors of the earth beneath us. Latest news

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025