M6 Rivet Nut Suppliers for Quality Fastening Solutions and Products

Oct . 02, 2024 03:37 Back to list

M6 Rivet Nut Suppliers for Quality Fastening Solutions and Products

Understanding M6 Riv Nuts and Their Suppliers

M6 riv nuts, also known as blind rivet nuts, are essential fasteners that enable effective attachment of components in various manufacturing and assembly applications. Their versatility makes them popular among engineers and manufacturers in sectors like automotive, aerospace, electronics, and construction. This article explores the significance of M6 riv nuts, their applications, and how to find reliable suppliers.

What are M6 Riv Nuts?

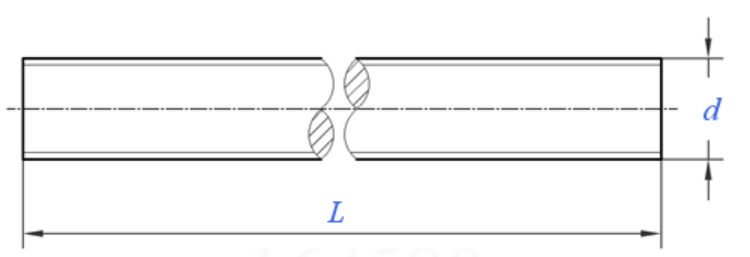

Riv nuts are cylindrical inserts that provide a strong threaded hole in thin materials where a standard threaded fastener would otherwise be impractical. The M6 designation refers to the metric thread size of 6mm. M6 riv nuts are typically made from materials such as steel, aluminum, or brass, offering varying strengths and corrosion resistance depending on their application.

Applications of M6 Riv Nuts

The primary function of M6 riv nuts is to securely join components, especially in scenarios where access to the rear side of the material is limited

. They are extensively used in1. Automotive Industry M6 riv nuts are utilized in vehicle assembly for attaching body panels, interior components, and other fixtures, providing strength and durability. 2. Aerospace Due to their lightweight yet strong properties, they are ideal for assembling aircraft components, where reducing weight without sacrificing strength is crucial.

3. Electronics They are often used in the assembly of electronic enclosures, allowing secure mounting of internal components while maintaining a low profile.

4. Construction and Furniture M6 riv nuts enable easy assembly and disassembly in prefabricated panels or modular furniture designs.

m6 riv nuts suppliers

Sourcing Reliable M6 Riv Nut Suppliers

Finding a trustworthy supplier for M6 riv nuts is key to ensuring the quality of your assemblies. Here are some tips to help you choose the right supplier

1. Quality Assurance Look for suppliers who adhere to international quality standards. Certifications like ISO 9001 can be a good indicator of a supplier's commitment to quality.

2. Material Options Evaluate suppliers based on the range of materials they offer. For instance, if your application requires corrosion-resistant materials, ensure that the supplier can provide options like stainless steel or coated riv nuts.

3. Customization Services Some projects may require specific dimensions, finishes, or thread forms. Suppliers that offer customization can help accommodate unique requirements.

4. Customer Support Reliable suppliers should provide strong customer support, helping you with product selection, technical advice, and after-sales service.

5. Reviews and Reputation Research customer reviews and testimonials to gauge the reputation of potential suppliers. A supplier with a track record of timely delivery and product reliability is often preferable.

In conclusion, M6 riv nuts play a crucial role in a wide variety of applications, providing strong and reliable fastening solutions. By sourcing them from reputable suppliers, manufacturers can ensure the quality and performance of their finished products, thus enhancing overall operational efficiency.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025