long nuts and bolts manufacturer

Sep . 23, 2024 07:07 Back to list

long nuts and bolts manufacturer

The Evolution and Importance of Long Nuts and Bolts Manufacturing

In the ever-evolving landscape of manufacturing, the production of long nuts and bolts serves as a crucial component that underpins various industries. These seemingly simple yet essential fasteners are integral in ensuring the structural integrity and functionality of numerous products, from heavy machinery to consumer electronics. The evolution of their manufacturing not only highlights advancements in technology but also emphasizes the increasing demand for precision and reliability in an increasingly competitive market.

Historically, the manufacturing of nuts and bolts dates back centuries, but it was during the industrial revolution that the processes began to modernize significantly. The introduction of mechanized tools and the standardization of sizes allowed for mass production, which in turn facilitated the rapid growth of industries requiring these components. Today, long nuts and bolts are manufactured to meet specific industry standards and specifications, ensuring compatibility and performance across various applications.

The Evolution and Importance of Long Nuts and Bolts Manufacturing

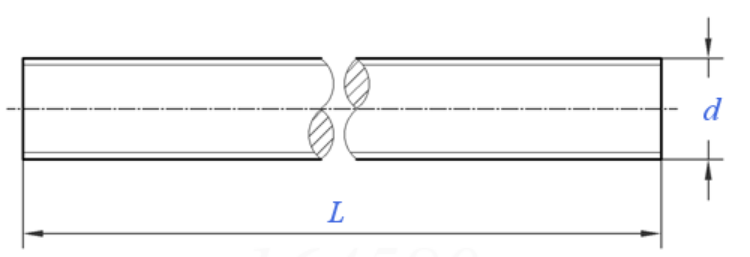

The manufacturing process itself has also seen significant advancements. Modern techniques such as cold heading, which involves shaping metal at room temperature, allow for greater precision and strength in the final product. Additionally, innovations in machining processes, such as CNC (computer numerical control) technology, enable manufacturers to produce long nuts and bolts with intricate designs and exact specifications, reducing waste and increasing efficiency.

long nuts and bolts manufacturer

Quality control is another vital aspect of the manufacturing process. Reputable manufacturers implement rigorous testing procedures to ensure that their products meet national and international standards. This includes tensile strength testing, torque testing, and corrosion resistance evaluations, ensuring that the final products are reliable and safe for use in critical applications.

In recent years, the demand for long nuts and bolts has surged, driven by growth in sectors such as automotive, construction, aerospace, and renewable energy. Manufacturers are responding to this demand by adopting sustainable practices, including the use of recyclable materials and energy-efficient production techniques. This shift not only benefits the environment but also positions manufacturers as responsible players in an increasingly eco-conscious marketplace.

Furthermore, customization has become a hallmark of modern long nuts and bolts manufacturing. Clients often require specific dimensions, coatings, or threads tailored to their unique applications. Forward-thinking manufacturers recognize the importance of flexibility and are investing in technologies that allow them to respond quickly to customer demands without compromising on quality.

In conclusion, the manufacturing of long nuts and bolts is a sophisticated and dynamic field that continues to evolve as technology advances and market demands shift. From material selection to production techniques, and quality assurance to sustainability practices, every aspect is geared towards producing high-quality fasteners that play a crucial role in the safety and effectiveness of countless products. As industries continue to innovate and expand, the importance of reliable nuts and bolts will undoubtedly persist, ensuring that these small but mighty components remain at the heart of manufacturing excellence.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025