Reliable Suppliers for Long Bolts and Fasteners You Can Trust

Nov . 07, 2024 08:38 Back to list

Reliable Suppliers for Long Bolts and Fasteners You Can Trust

The Essential Role of Long Bolts Suppliers in Various Industries

In the complex world of manufacturing and construction, long bolts play a crucial role. These fasteners are essential for securing components together, ensuring structural integrity and safety in a plethora of applications. Whether in heavy machinery, automotive assembly, bridge construction, or even furniture making, long bolts are ubiquitous. In this context, long bolts suppliers take center stage, providing businesses with the high-quality components they need for successful projects.

Understanding Long Bolts

Long bolts, typically defined as fasteners longer than six inches, are made from various materials such as stainless steel, carbon steel, and alloy steel. The choice of material often depends on the specific application and environmental conditions they will face. For instance, stainless steel bolts are preferred in coastal regions due to their resistance to corrosion, while carbon steel bolts are often used for their strength in more controlled environments.

These bolts come in various sizes and specifications, providing flexibility to designers and engineers. Their applications are diverse, ranging from holding together large structural components in buildings to fastening together parts in automotive manufacturing. The performance of these bolts can significantly impact the reliability and safety of the end product.

The Importance of Quality

For businesses relying on long bolts, the quality of their suppliers is paramount. A reputable long bolts supplier will adhere to strict manufacturing standards, ensuring that each bolt meets industry specifications. This includes aspects like tensile strength, yield strength, and resistance to fatigue. The failure of a long bolt due to subpar quality can result in catastrophic consequences, making it critical for suppliers to maintain high standards.

Quality assurance processes such as material inspections, regular testing, and certifications are essential. Many suppliers also provide documentation to support their products, including test reports and compliance with relevant industry standards, such as ISO or ASTM certifications. This level of transparency helps businesses make informed decisions and enhances trust in the supplier-client relationship.

Customization and Variety

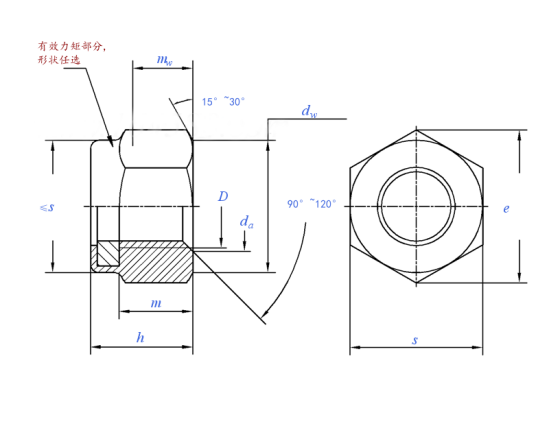

long bolts supplier

Another significant advantage of working with a long bolts supplier is their ability to provide customized solutions. Different projects may require specific lengths, diameters, or threading types. A good supplier will work with clients to understand their particular needs and produce tailored bolts that meet those specifications. This capability to customize products is especially important in industries such as aerospace and automotive, where precision is critical.

Moreover, suppliers often maintain a wide inventory of standard sizes and types, allowing for quick turnarounds. This can be a significant advantage for businesses that require a rapid supply chain response, minimizing downtime and ensuring that projects stay on schedule.

The Role of Technology

In recent years, technology has revolutionized the supply chain management of long bolts. Suppliers are utilizing advanced inventory management systems to track stock levels and forecast demand accurately. Techniques such as Just-In-Time (JIT) inventory reduce excess stock while ensuring that products are readily available when needed.

Additionally, 3D printing technologies are beginning to emerge in the production of bolts and fasteners. This new approach allows for rapid prototyping and production of bespoke items, enabling suppliers to meet the unique needs of various sectors, especially in spaces where traditional manufacturing may fall short.

Sustainability Considerations

As industries become increasingly aware of their environmental impact, suppliers of long bolts are also adapting by providing more sustainable options. This includes sourcing materials responsibly and developing manufacturing processes that reduce waste and energy consumption. Offering recycled materials or designing bolts that are easier to disassemble can significantly contribute to sustainability goals in construction and manufacturing.

Conclusion

Long bolts suppliers are indispensable partners in the various industries that rely on these critical components. Their commitment to quality, customization, and innovation ensures that businesses can undertake their projects confidently. As technology and environmental considerations evolve, these suppliers will continue to play a vital role in shaping the future of manufacturing and construction. By understanding the significance of long bolts and their suppliers, companies can better appreciate the intricacies involved in creating safe and reliable structures and products.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025