lift support sleeve stud bolt suppliers

Nov . 17, 2024 20:25 Back to list

lift support sleeve stud bolt suppliers

Understanding Lift Support Sleeve Stud Bolts and Finding Reliable Suppliers

In the world of industrial applications, the lift support sleeve stud bolts play a crucial role in ensuring the stability and reliability of various structures and equipment. These components are essential in a wide range of applications, from automotive to construction, where they provide the necessary tensile strength and support required to withstand heavy loads. As industries continue to evolve, the demand for high-quality lift support sleeve stud bolts has surged, making it imperative for businesses to find reliable suppliers.

What Are Lift Support Sleeve Stud Bolts?

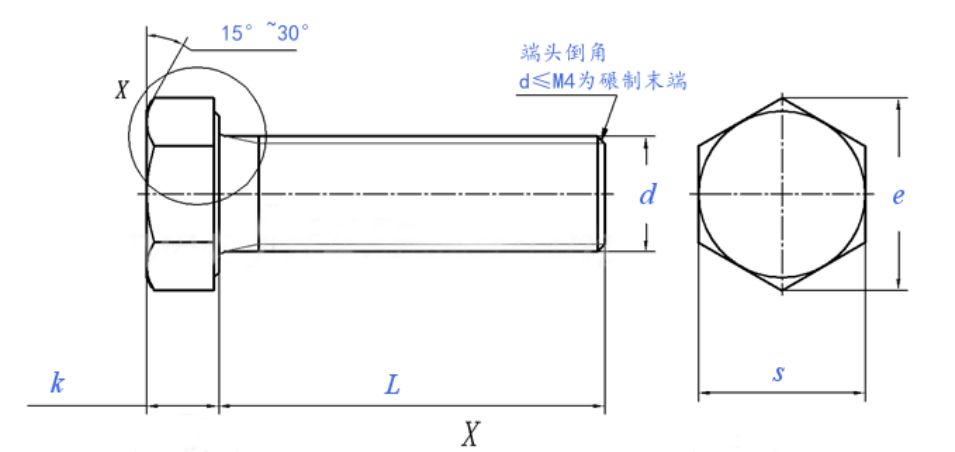

Lift support sleeve stud bolts are specialized fasteners designed to support the weight of heavy components by securing them tightly together. They often feature a threaded design that allows for easy installation and adjustment, providing a versatile solution for various engineering challenges. The sleeve aspect refers to the additional component that helps distribute the load more evenly, reducing stress on the bolt and the materials being secured.

Typically made from high-strength materials such as stainless steel or carbon steel, these bolts offer excellent corrosion resistance and durability, essential for use in demanding environments. Industries like automotive manufacturing, construction, and heavy machinery rely on these fasteners to ensure the integrity of their structures and equipment.

Importance of Quality and Standards

When selecting lift support sleeve stud bolts, quality is paramount. Poorly manufactured bolts can lead to structural failures, posing safety risks and resulting in costly downtime. Therefore, it’s crucial for suppliers to adhere to strict industry standards such as ASTM, ISO, and ANSI. These standards ensure that the fasteners meet specific performance and safety criteria, making them suitable for their intended applications.

High-quality lift support sleeve stud bolts should withstand various environmental factors, including extreme temperatures, moisture, and chemicals

. Additionally, the correct heat treatment and surface finishing processes can enhance the strength and longevity of these components.Finding Reliable Suppliers

lift support sleeve stud bolt suppliers

With the increasing demand for lift support sleeve stud bolts, numerous suppliers have entered the market. However, not all suppliers are created equal. Here are some key factors to consider when searching for reliable suppliers

1. Industry Reputation Look for suppliers with proven track records and positive reviews. Checking references and client testimonials can provide insights into their reliability and product quality.

2. Certifications and Compliance Ensure that the supplier adheres to recognized standards and certifications. This demonstrates their commitment to quality and safety.

3. Product Range and Customization A good supplier should offer a diverse range of lift support sleeve stud bolts, accommodating various sizes, materials, and specifications. Additionally, they should have the capability to provide custom solutions based on specific client needs.

4. Technical Support and Expertise Suppliers should offer technical assistance, helping clients choose the right fasteners for their applications. Their expertise can be invaluable in ensuring optimal performance.

5. Lead Time and Delivery Delivery timelines are critical in many industrial projects. Choose a supplier that can meet your deadlines and provide timely delivery without compromising quality.

6. Pricing and Warranty Compare pricing among different suppliers, but remember that the cheapest option may not always be the best. Look for a balance between cost and quality. Additionally, a warranty can provide peace of mind regarding the product’s performance.

Conclusion

Lift support sleeve stud bolts are indispensable in various industries, but their efficacy relies heavily on the quality of the fasteners. By carefully selecting reliable suppliers, businesses can ensure that they have access to high-quality components that enhance safety and performance. Investing time into finding the right supplier will pay off in the long run, contributing to operational efficiency and the longevity of projects. Whether in automotive manufacturing or construction, the right lift support sleeve stud bolts will provide the essential support and stability needed to withstand the demands of modern engineering.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025