Leading Manufacturer of Precision Stainless Steel Shims and Washers for Various Applications

Aug . 05, 2024 20:22 Back to list

Leading Manufacturer of Precision Stainless Steel Shims and Washers for Various Applications

The Significance of Stainless Steel Shims and Washers in Industries

In the multifaceted world of manufacturing and engineering, the demand for precision and durability in components is paramount. Among the various tools and implements that play pivotal roles in assembly processes, stainless steel shims and washers stand out due to their extensive applications and remarkable performance. This article delves into the significance of these components, particularly focusing on the role of manufacturers who specialize in their production.

Understanding Stainless Steel Shims and Washers

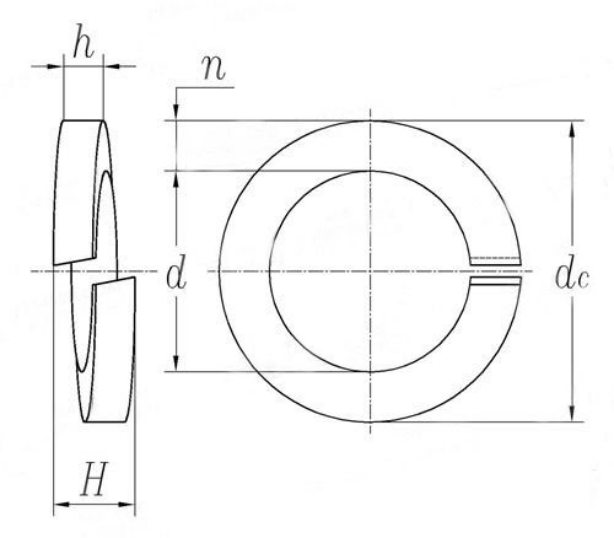

Shims are thin pieces of material used to fill gaps or provide support, whereas washers are flat discs placed under nuts, bolts, or screws to distribute load, reduce friction, or act as a spacer. Both items are crucial in numerous applications across industries such as automotive, aerospace, construction, and electronics. The material choice greatly influences their performance, and stainless steel has proven to be one of the most effective materials due to its strength, corrosion resistance, and overall longevity.

Advantages of Stainless Steel

Stainless steel is renowned for its resistance to rust, staining, and corrosion, making it ideal for environments that may involve exposure to moisture or chemicals. The unique properties of stainless steel—such as high tensile strength and ability to withstand extreme temperatures—ensure that shims and washers can maintain their integrity under varying conditions. This is especially critical in sectors like aerospace and automotive, where safety and reliability are non-negotiable.

Moreover, stainless steel’s aesthetic appeal and ability to be sanitized easily make it a preferred choice in industries such as food processing and pharmaceuticals, where hygiene is a top priority

.The Role of Manufacturers

stainless steel shims washers manufacturer

Manufacturers who specialize in stainless steel shims and washers play a critical role in ensuring the quality, precision, and availability of these components. The production process typically involves cutting, shaping, and finishing stainless steel into the required dimensions and specifications. Advanced technologies such as laser cutting, CNC machining, and stamping are often employed to achieve the necessary precision.

Quality control is another vital aspect of manufacturing. Reputable manufacturers implement stringent quality assurance measures to ensure that every shim and washer meets industry standards. This includes testing for strength, durability, and dimensional accuracy. By adhering to such rigorous standards, manufacturers help prevent equipment failures and costly downtime for their clients.

Customization and Versatility

One of the defining characteristics of stainless steel shims and washers is their customizability. Manufacturers can tailor these components to meet specific requirements, including size, thickness, and finish. This adaptability allows businesses in various sectors to find solutions that perfectly fit their unique applications.

For instance, in electrical equipment, specific washers may be required to accommodate insulation and conductivity. In construction, shims may need to be tailored to fit architectural designs and load-bearing requirements. By collaborating with manufacturers, clients can optimize their assembly processes and enhance overall product performance.

Conclusion

In summary, stainless steel shims and washers are essential components that contribute to the effectiveness and longevity of mechanical systems across various industries. The expertise of dedicated manufacturers not only ensures the production of high-quality components but also allows for customization that meets the specific needs of different applications. As industries continue to evolve, the importance of reliable and durable components made from materials like stainless steel will undoubtedly remain a cornerstone of efficient manufacturing and engineering practices.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025