Leading Manufacturer of Left-Hand Threaded Hex Bolts for Diverse Industrial Applications

Aug . 01, 2024 00:36 Back to list

Leading Manufacturer of Left-Hand Threaded Hex Bolts for Diverse Industrial Applications

Understanding Left-Hand Threaded Hex Bolts and Their Manufacturing

In the world of fasteners, bolts, and nuts, the left-hand threaded hex bolt is a specialized component that plays a significant role in various applications, especially where reverse rotation is anticipated. These bolts are designed with a counterclockwise thread direction, which is essential for specific mechanical setups where traditional right-hand threads could loosen due to vibration or motion.

What are Left-Hand Threaded Hex Bolts?

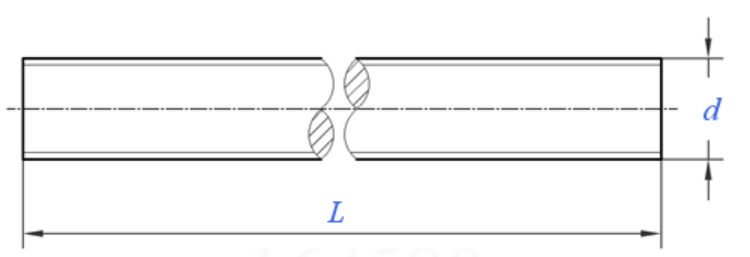

Left-hand threaded hex bolts are characterized by their hexagonal heads and a thread that spirals in a leftward direction. The unique threading allows them to provide a secure fastening solution in situations where a standard right-hand threaded bolt may fail. Common materials used for these bolts include steel, stainless steel, and various alloys to ensure strength and resistance to corrosion.

The hexagonal design of the bolt head enables effective tightening using traditional wrenches, promoting ease of application and maintenance. In contrast to their right-hand counterparts, left-hand bolts are often used in specialized situations, such as in certain types of machinery, automotive applications, and even in applications involving a rotating shaft where the direction of motion would tend to loosen a right-hand threaded bolt.

Applications and Importance

Left-hand threaded bolts can be seen prominently in a variety of fields. For instance, they are commonly used in bicycle pedals where the left pedal is typically designed to counteract the loosening forces generated by pedaling. Similarly, they find utility in heavy machinery, automotive components, and in setups that involve conveyor belts and rotating equipment.

left-hand threaded hex bolt manufacturer

One interesting application is in the assembly of certain types of gas and steam turbines, where the rotation can lead to the inadvertent loosening of standard bolts. By utilizing left-hand threaded bolts in these critical applications, manufacturers ensure a stable and secure connection that can withstand the rigors of operational stress.

Manufacturing Process

The production of left-hand threaded hex bolts involves several key steps. First, high-quality raw materials are sourced, which are essential for ensuring the strength and durability of the final product. Next, the manufacturing process begins with cold or hot forging, depending on the desired properties of the bolt.

Once the basic shape is formed, the threads are cut or rolled to create the left-hand configuration. The precision in this process is vital, as any inconsistency can compromise the bolt’s performance. Advanced machinery and techniques, such as CNC machining and thread rolling, are often employed to create high-quality threads that meet stringent tolerances.

After threading, the bolts are typically heat-treated to enhance their strength and hardness. Surface treatments, such as galvanization or nickel plating, may also be applied to prevent corrosion and increase the lifespan of the bolts. Finally, quality control measures are implemented to ensure that each bolt meets industry standards and specifications.

Conclusion

Left-hand threaded hex bolts are a critical component in various mechanical systems, offering solutions where conventional fastening methods may fail. Their specialized design and manufacturing process allow them to perform reliably in settings that demand robustness and precision. As industries evolve and technological advancements continue, the demand for specialized fasteners like left-hand threaded bolts is expected to grow, underscoring their importance in modern engineering and manufacturing contexts. Understanding the characteristics, applications, and manufacturing processes of these bolts is essential for professionals in the field, ensuring the right components are used in the right applications for optimal performance.

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025