Premium Serrated Hex Head Stud Bolts for Enhanced Performance and Reliability

Nov . 09, 2024 01:51 Back to list

Premium Serrated Hex Head Stud Bolts for Enhanced Performance and Reliability

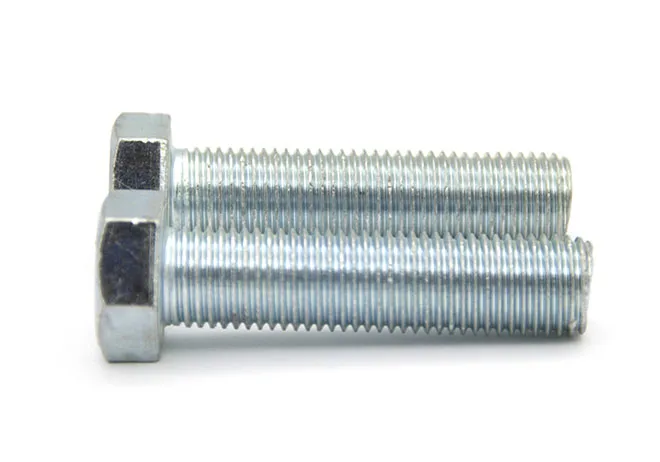

High-Quality Stud Bolt Serrated Hex Head An Overview

In the world of mechanical engineering and construction, fasteners play a crucial role in ensuring the stability, integrity, and longevity of various structures and assemblies. Among the myriad types of fasteners available, the stud bolt with a serrated hex head stands out due to its unique design and enhanced performance features. This article explores the significance, advantages, manufacturing processes, and applications of high-quality stud bolts with serrated hex heads, emphasizing why they are preferred in demanding environments.

Understanding Stud Bolts

Stud bolts are specialized fasteners that consist of a cylindrical rod with threads on both ends. They are commonly used to connect two or more components, where one end is typically anchored in place while the other receives a nut. The design of stud bolts allows them to provide a strong and reliable connection, making them ideal for high-stress applications.

What is a Serrated Hex Head?

The hex head is a common design for fasteners that feature six flat sides, allowing for easy grip and torque application using standard tools. A serrated hex head takes this design a step further by incorporating serrations or notches along the flat surface. These serrations enhance the friction between the bolt and the surface of the material it is fastening, creating a superior grip that is resistant to loosening due to vibrations or mechanical movement.

Advantages of High-Quality Stud Bolts with Serrated Hex Heads

1. Enhanced Grip and Stability The serrated design of the hex head ensures a stronger grip during installation and use. This is particularly beneficial in applications where frequent vibrations occur, such as in heavy machinery or automotive environments, where traditional smooth fasteners may loosen over time.

2. Ease of Installation The hexagonal shape of the head allows for easy engagement with standard wrenches, facilitating quick and efficient installation and removal. The added serrations provide extra traction, reducing the risk of slipping during the fastening process.

3. Versatility High-quality stud bolts with serrated hex heads are available in various sizes, materials, and coatings, making them suitable for a wide range of applications from construction to manufacturing to automotive industries. They can be made from materials such as stainless steel, carbon steel, or alloyed steel, each offering different levels of corrosion resistance and strength.

4. Increased Durability Quality manufacturing processes ensure that these fasteners can withstand harsh environmental conditions, including high temperatures and corrosive environments. This durability translates to longer life cycles for structures and components, reducing the need for replacements and maintenance.

high quality stud bolt serrated hex head

Manufacturing Processes

The production of high-quality stud bolts with serrated hex heads typically involves several key steps

1. Material Selection The choice of materials is crucial for ensuring strength and durability. High-quality steel grades or alloys are often chosen based on the intended application and environmental conditions.

2. Forging and Machining The raw materials undergo forging to create the basic shape of the bolt. This is followed by precision machining processes to create threads and form the hex head, including the serrations.

3. Heat Treatment Many manufacturers apply heat treatment to enhance the strength and toughness of the bolts. This process involves heating the bolts to high temperatures and then rapidly cooling them, resulting in improved mechanical properties.

4. Coating and Finishing Finally, the bolts may receive surface treatments or coatings, such as zinc plating or powder coating, to enhance corrosion resistance and provide additional durability.

Applications

High-quality stud bolts with serrated hex heads are used extensively in various industries due to their reliability and strength. Common applications include

- Construction Used to secure structural steel components, where stability is paramount. - Automotive Critical for assembling engines and other high-vibration components. - Manufacturing Employed in machinery where fasteners must endure physical stresses.

Conclusion

High-quality stud bolts with serrated hex heads represent a critical component in the realm of engineering and construction. Their design offers numerous advantages, including enhanced grip, durability, and ease of use, making them indispensable in high-stress environments. As industries continue to advance, the demand for reliable and efficient fasteners will only grow, solidifying the role of stud bolts with serrated hex heads as key players in building and maintaining robust structures and machinery.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025