high quality stud bolt m20

Oct . 05, 2024 16:22 Back to list

high quality stud bolt m20

The Importance of High-Quality Stud Bolts A Focus on M20 Specifications

Stud bolts are essential components in various industries, particularly in construction, manufacturing, and engineering. They are threaded rods that provide a secure fastening method, connecting two or more parts together to form a robust assembly. High-quality stud bolts, particularly the M20 specifications, are indispensable for ensuring safety and reliability in diverse applications.

Understanding M20 Stud Bolts

The term M20 refers to the metric size of the stud bolt, where 'M' indicates that it is a metric threaded fastener and '20' signifies the nominal diameter of 20 millimeters. The M20 size is widely used in applications requiring significant strength and stability, such as heavy machinery, structural frameworks, and high-pressure systems. The design and material selection of M20 stud bolts are crucial for their overall performance.

Material Composition

High-quality stud bolts are typically made from high-strength steel, often treated for enhanced durability. Common materials include carbon steel, stainless steel, and alloy steel. Each material has its specific benefits; for instance, stainless steel offers excellent corrosion resistance, making it ideal for marine applications or environments with high humidity. On the other hand, alloy steels are preferred in scenarios demanding superior strength and toughness.

Manufacturing Standards

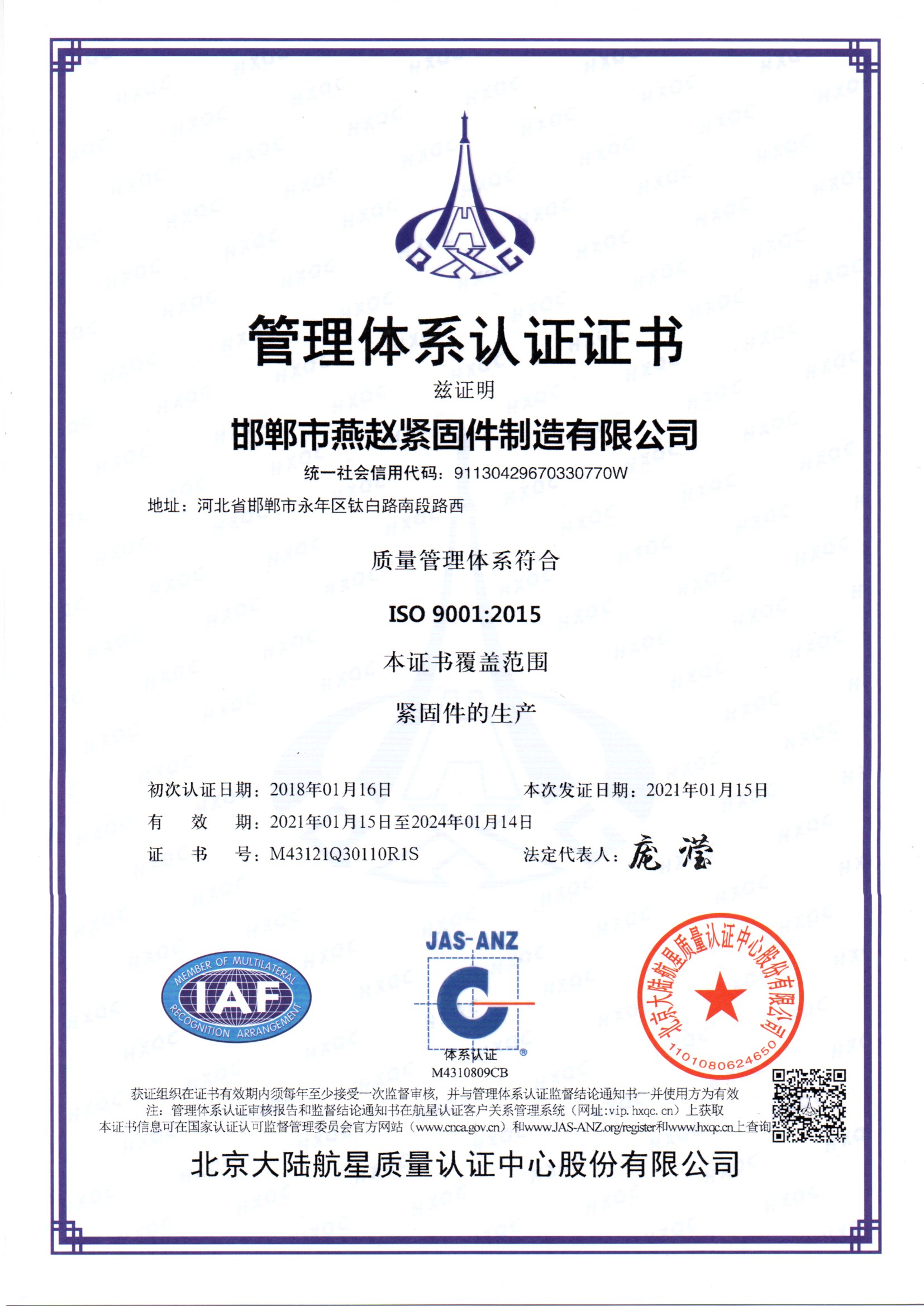

To label stud bolts as high-quality, they must adhere to stringent manufacturing standards. International standards such as ISO and ASTM provide guidelines to ensure the mechanical properties, reliability, and durability of stud bolts. High-quality M20 stud bolts are usually manufactured with attention to detail, which includes precise threading, consistent widths, and appropriate coatings to minimize corrosion or wear.

high quality stud bolt m20

The Role of Coatings

Many high-quality stud bolts feature protective coatings, which can include zinc plating, hot-dip galvanizing, or additional polymer coatings. These coatings serve various purposes they enhance corrosion resistance, improve aesthetics, and reduce friction during installation and operation. The choice of coating depends on the application environment and specific requirements of the end-user.

Importance in Structural Integrity

The structural integrity of any assembly greatly depends on the quality of its fastening components. M20 stud bolts are used in critical applications where failure can lead to catastrophic results, such as in bridges, high-rise buildings, and pressure vessels. Using high-quality studs ensures that the connections can withstand significant loads, vibrations, and environmental factors, thereby enhancing safety and extending the life of the structure.

Installation Practices

Proper installation of M20 stud bolts is vital to achieve optimal performance. This includes ensuring that the threads are properly aligned, using the right amount of torque, and maintaining appropriate tension during the fastening process. In industrial settings, employing torque wrenches and following manufacturer guidelines can significantly reduce the risk of joint failure caused by over-tightening or under-tightening.

Conclusion

In summary, high-quality M20 stud bolts play a pivotal role in various applications, from construction to manufacturing. Their ability to provide reliable fastening solutions while adhering to strict standards of quality and safety distinguishes them as a crucial component in any assembly. As industries continue to evolve, the demand for high-quality fastening solutions like M20 stud bolts will only increase, emphasizing the importance of material selection, manufacturing practices, and proper installation techniques. Investing in high-quality stud bolts ultimately leads to safer, more durable constructions and machinery, fulfilling the essential requirements of modern engineering and safety standards.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025