High-Quality OEM Cap Head Hexagon Socket Bolts for Durable and Reliable Fastening Solutions

Aug . 01, 2024 08:11 Back to list

High-Quality OEM Cap Head Hexagon Socket Bolts for Durable and Reliable Fastening Solutions

Understanding OEM Cap Head Hexagon Socket Bolts

In the world of manufacturing and assembly, the choice of components plays a critical role in the overall performance and reliability of a product. Among the myriad types of fasteners available, OEM (Original Equipment Manufacturer) cap head hexagon socket bolts have emerged as a preferred choice in various industries. This article delves into the characteristics, applications, and advantages of these specialized bolts, highlighting their significance in contemporary manufacturing.

What are OEM Cap Head Hexagon Socket Bolts?

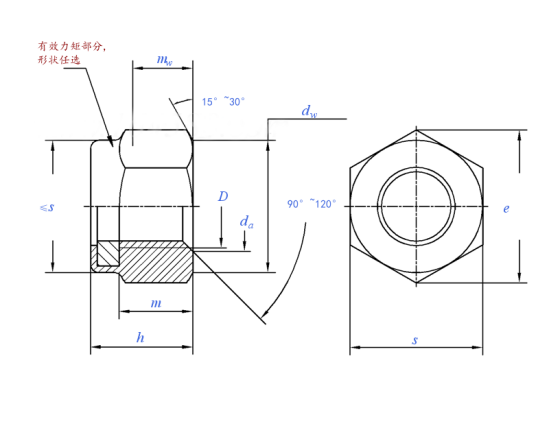

OEM cap head hexagon socket bolts are a type of fastener characterized by their cylindrical head and a hexagonal recess designed to accommodate a hex key or Allen wrench. The cap head design provides a clean and aesthetically pleasing appearance, often utilized in applications where the appearance of the fastener matters. Additionally, the hexagon socket allows for greater torque application compared to standard screws, facilitating the assembly process.

These bolts are typically made from high-quality materials such as stainless steel, carbon steel, or alloy steel, ensuring durability, resistance to corrosion, and high tensile strength. The choice of material is essential, as it can influence the performance of the bolt in different environments, making OEM cap head hexagon socket bolts ideal for various applications ranging from automotive to electronics and heavy machinery.

Applications of OEM Cap Head Hexagon Socket Bolts

The versatility of OEM cap head hexagon socket bolts allows them to be utilized in numerous industries. A few notable applications include

1. Automotive Industry These bolts are commonly used in vehicle assembly due to their strength and reliability. They can be found in engine components, body panels, and other critical areas where secure fastening is essential.

2. Electronics The compact design of cap head hexagon socket bolts makes them suitable for electronic enclosures and devices where space is limited. Their secure fastening capability protects sensitive components from vibration and mechanical stress.

oem cap head hexagon socket bolts

3. Construction and Heavy Machinery In the construction industry, these bolts are used to assemble structural components, ensuring stability and safety. Heavy machinery also relies on cap head hexagon socket bolts for secure joints, particularly where high loads are involved.

4. Furniture and Fixtures The aesthetic appeal of cap head bolts makes them a popular choice in furniture design, where visible fasteners can complement the overall look of a piece.

Advantages of Using OEM Cap Head Hexagon Socket Bolts

1. Ease of Use The hexagonal socket design allows for easy installation and removal, especially in tight spaces where traditional wrenches might not fit. This efficiency saves time during assembly and maintenance.

2. Increased Torque The design facilitates greater torque application, enabling the bolt to withstand more significant forces without risking damage or loosening over time.

3. Aesthetically Pleasing The cap head provides a neat appearance, making these bolts ideal for applications where they may be visible.

4. Versatility With a wide range of sizes, materials, and finishes available, OEM cap head hexagon socket bolts can be tailored to meet the specific requirements of different projects and industries.

Conclusion

OEM cap head hexagon socket bolts are indispensable components in modern manufacturing and assembly processes. Their unique design and robust performance make them suitable for a wide array of applications, from automotive to electronics and beyond. By understanding their characteristics and advantages, manufacturers can make informed decisions, ensuring the quality and longevity of their products. As technology continues to advance, the role of these versatile fasteners will undoubtedly evolve, further solidifying their place in the industrial landscape.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025