High-Quality OEM Bolts for Decks to Enhance Structural Integrity and Long-lasting Performance

Jul . 30, 2024 14:39 Back to list

High-Quality OEM Bolts for Decks to Enhance Structural Integrity and Long-lasting Performance

OEM Bolts for Decks Ensuring Quality and Durability in Marine Applications

When it comes to constructing or refurbishing decks, especially in marine environments, the choice of materials is paramount. Among these materials, bolts play a critical role in the structural integrity and longevity of the deck. OEM bolts, or Original Equipment Manufacturer bolts, are increasingly becoming the go-to option for builders and contractors seeking to ensure quality and reliability in their projects.

Understanding OEM Bolts

OEM bolts are specifically designed and manufactured to meet the exact specifications of original equipment used in various applications, including marine decking systems. This means that when you choose OEM bolts, you are opting for components that are made to fit perfectly and function optimally with your deck materials. Unlike generic or aftermarket options, which may vary in size, strength, and quality, OEM bolts provide a level of assurance that they will perform as intended.

The Importance of Quality in Marine Decking

Decks exposed to marine environments encounter unique challenges such as saltwater corrosion, UV degradation, and the constant stress of environmental changes. Therefore, the quality of the hardware used in these constructions is crucial. OEM bolts are often made from superior materials, such as stainless steel or marine-grade alloys, which offer enhanced resistance against corrosion and wear. This is essential for maintaining the structural integrity of the deck and ensuring safety for users.

Moreover, the precision manufacturing of OEM bolts means that their tolerances are tightly controlled, which helps in achieving optimal load distribution. This is particularly important for decks that experience heavy foot traffic or the weight of marine equipment. The proper fit of OEM bolts reduces the likelihood of loosening over time, which can lead to structural failures.

Choosing the Right OEM Bolts for Your Deck

When selecting OEM bolts for your deck, it’s important to consider several factors, including

1. Material As mentioned, choosing the right material is critical. Marine-grade stainless steel is often preferred for its corrosion resistance, but other options may also be suitable depending on the specific environmental conditions.

oem bolts for deck

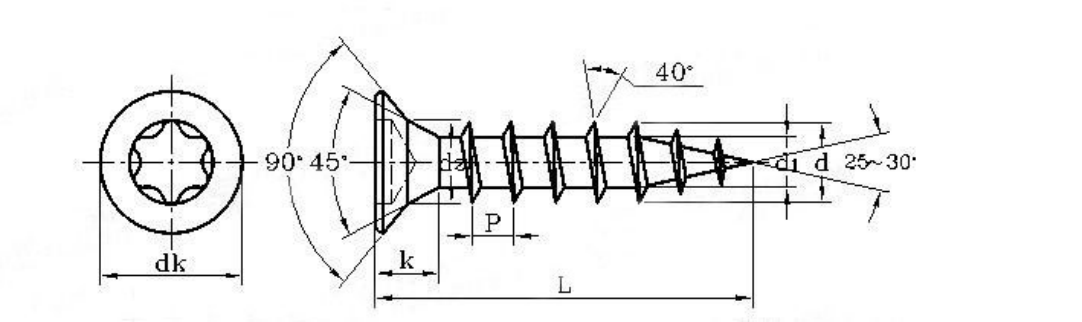

2. Size and Length Ensure that the bolts you choose are the correct size and length for your decking materials. This will ensure a secure fit and optimal performance.

3. Thread Type Different applications may require specific thread types, whether coarse or fine. Make sure to choose the right thread configuration for the materials you are working with.

4. Manufacturer Specifications Always refer to the manufacturer’s specifications for the deck system you are using. This will guide you in selecting compatible OEM bolts that are designed for optimal performance with that specific decking material.

The Benefits of Using OEM Bolts

Investing in OEM bolts for your decking project yields several benefits

- Reliability OEM bolts provide a proven track record of quality and performance, reducing the risk of unexpected failures.

- Longevity Their durability ensures that your deck remains safe and functional for years, minimizing the need for repairs or replacements.

- Ease of Installation OEM bolts are designed to fit perfectly with the accompanying materials, making installation smoother and more efficient.

In conclusion, when it comes to constructing a reliable and long-lasting deck, especially in marine applications, the choice of hardware is critical. OEM bolts offer quality, durability, and peace of mind, making them an ideal choice for builders and contractors. By opting for OEM components, you ensure that your deck not only meets but exceeds the necessary standards for safety and performance, allowing users to enjoy their outdoor spaces with confidence.

Latest news

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier

NewsAug.12,2025

-

Leading Phosphated Drywall Screws Supplier | Bulk & Custom Orders

NewsAug.11,2025

-

Top Wire Bolts Company: Manufacturers, Exporters & Suppliers

NewsAug.10,2025