High-Quality M6x16 Stud Bolt Manufacturer for Reliable and Durable Fastening Solutions

Aug . 05, 2024 18:11 Back to list

High-Quality M6x16 Stud Bolt Manufacturer for Reliable and Durable Fastening Solutions

Understanding the Significance of the M6x16 Stud Bolt A Focus on Manufacturer Quality

In the vast realm of engineering and construction, fasteners play a critical role in ensuring structural integrity and reliability. Among these fasteners, the stud bolt stands out for its versatility and strength, particularly the M6x16 stud bolt. This article delves into the importance of M6x16 stud bolts, the manufacturing process, and the factors that contribute to selecting a reputable manufacturer.

What is an M6x16 Stud Bolt?

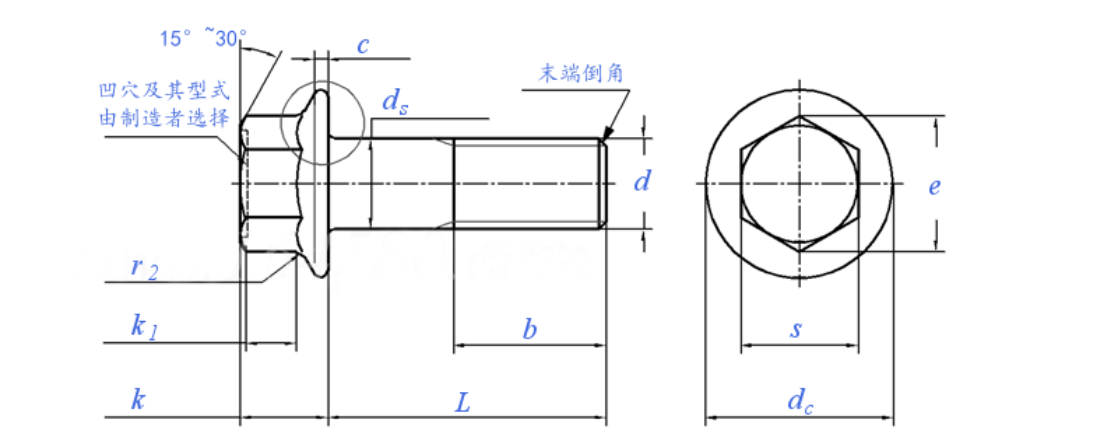

An M6x16 stud bolt is a type of fastener characterized by its dimension an M6 designation indicates a nominal diameter of 6 millimeters, while the 16 refers to its length, which is 16 millimeters. Stud bolts are typically used in pairs, with nuts that are tightened on either end to secure two parts together, making them ideal for applications where a bolted connection is required. This specific size is commonly used in various applications ranging from automotive to construction and machinery assembly.

The Manufacturing Process

The quality of a stud bolt hinges on its manufacturing process. Most stud bolts are produced from high-grade materials, such as carbon steel or stainless steel, which offer excellent strength and corrosion resistance.

1. Material Selection The first step in manufacturing an M6x16 stud bolt is selecting the appropriate raw materials. Manufacturers often choose materials based on the intended application and environmental conditions. For instance, stainless steel may be preferred in corrosive environments.

2. Forging and Machining The chosen material is subjected to forging, where it is heated and shaped into a rough form. Following this, precision machining is conducted to achieve the exact dimensions of M6x16. This phase is critical to ensure that the threads and surface finishes meet industry standards.

3. Heat Treatment Heat treatment processes, such as quenching and tempering, are applied to enhance the mechanical properties of the stud bolts. This process improves tensile strength and ductility, allowing the fasteners to withstand high stress.

4. Quality Control A reputable manufacturer implements stringent quality control measures. This includes inspections during various stages of production, culminating in final testing that checks for dimensional accuracy, tensile strength, and surface imperfections.

76640191a stud bolt m6x16 manufacturer

Choosing the Right Manufacturer

Selecting the right manufacturer for M6x16 stud bolts is vital to ensure safety and performance in applications. Here are some factors to consider

1. Certification and Standards Look for manufacturers that comply with international standards such as ISO or ASTM. Their certifications indicate adherence to quality benchmarks.

2. Reputation and Experience A manufacturer's experience in the industry often correlates with quality. Firms that have been in business for several years are likely to have refined their manufacturing processes and built a reputation for reliability.

3. Customer Reviews Feedback from previous customers can provide insights into the quality and performance of the fasteners. Check for reviews on multiple platforms to obtain a comprehensive view.

4. Customization Options Depending on specific project requirements, custom manufacturing options might be necessary. A good manufacturer should offer flexibility in terms of material types, coatings, and sizes.

5. Post-Production Support Inquire about warranty and post-production support services. Reliable manufacturers often provide assistance and guarantees for their products, ensuring customer confidence.

Conclusion

The M6x16 stud bolt is a fundamental component in various engineering and construction applications, and the quality of these fasteners can significantly impact project outcomes. A thorough understanding of the manufacturing process, along with careful selection of a reputable manufacturer, is essential in ensuring the safety, durability, and functionality of the connections in which these bolts are used. As industries continue to evolve, staying informed and making educated choices around fasteners will contribute to the overall success of engineering projects worldwide.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025