High-Quality Header Bolts for SBC Manufacturing and Performance Upgrades from Trusted Factory Sources

Jul . 30, 2024 00:08 Back to list

High-Quality Header Bolts for SBC Manufacturing and Performance Upgrades from Trusted Factory Sources

Header Bolts in SBC Factory A Crucial Component for Engine Performance

In the world of high-performance automotive engineering, every component plays a vital role in ensuring that an engine delivers optimal power and reliability. One such crucial component is the header bolt, especially in Small Block Chevy (SBC) engines, which have a rich history in motorsports and street performance applications. The header bolts are essential for securing the headers to the engine, ensuring a tight seal, and allowing the exhaust gases to escape efficiently.

Understanding Header Bolts

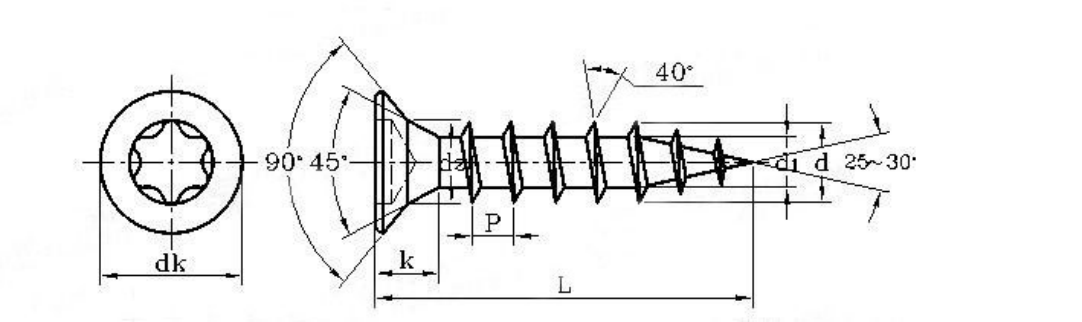

Header bolts are specialized fasteners designed specifically for attaching headers (exhaust manifold systems) to an engine's cylinder head. Unlike standard bolts, header bolts are often made of stronger materials, such as stainless steel or high-strength steel alloys, to withstand the extreme conditions of high temperatures and vibrations. A well-fitted header bolt must be able to endure the thermal expansion and contraction of metal that occurs during engine operation, as failure to do so can lead to exhaust leaks, performance issues, and unnecessary engine damage.

Importance in SBC Engines

The Small Block Chevy has long been a favorite among automotive enthusiasts due to its versatility, power potential, and relatively simple design. In SBC engines, the header bolts play a pivotal role, especially in high-performance builds where every facet can influence the overall output. When upgrading to performance headers, the choice of header bolts becomes even more critical.

High-performance headers are generally constructed to promote better exhaust flow, which directly impacts engine efficiency and power. However, if the header isn’t secured properly, the benefits gained from enhancing exhaust flow can be negated. Loose or inadequate header bolts can lead to exhaust leaks, resulting in a loss of power and increasing emissions. Furthermore, exhaust leaks can also impact the performance of oxygen sensors, leading to complications in engine tuning and fuel economy.

header bolts sbc factory

Choosing the Right Header Bolts

When it comes to selecting the right header bolts for an SBC factory or aftermarket installation, several factors need consideration. Firstly, one must evaluate the material of the bolts—stainless steel is often preferred due to its corrosion resistance and durability, whereas some may opt for titanium for weight savings, albeit at a higher cost.

Secondly, the length and threading of the header bolts should align with the specific SBC model and the header design. Using bolts that are too short or improperly threaded can lead to installation issues and potentially catastrophic engine failures. Additionally, it's crucial to use locking washers or flanged bolts to prevent them from loosening over time due to vibration.

Installation and Maintenance Tips

Proper installation of header bolts is essential for long-term performance. It is advisable to follow a sequence when tightening the bolts, typically in a crisscross pattern, to ensure even pressure distribution. Furthermore, it is wise to periodically check the tightness of the header bolts, especially after the initial installation and after the first few heat cycles of the engine. This will help avoid the common problem of header bolts loosening over time.

Conclusion

In summary, header bolts might seem like a small component in the grand scheme of an engine's performance, but their role is undeniably significant, particularly in Small Block Chevy applications. By selecting the right materials, ensuring proper installation, and maintaining the hardware, automotive enthusiasts can maximize their SBC's potential and enjoy a reliable and powerful driving experience. Whether for street use or racing, paying attention to the details, like header bolts, can make all the difference in engine performance and durability.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025