heavy flat washers factory

Sep . 22, 2024 20:01 Back to list

heavy flat washers factory

Heavy Flat Washers Factory Ensuring Quality and Precision in Manufacturing

In the realm of industrial manufacturing, the significance of high-quality components cannot be overstated. Among these components, heavy flat washers play a crucial role in various applications, providing essential support and stability to bolted connections. Understanding the manufacturing process and the factors that contribute to a leading heavy flat washers factory is vital for industries that require dependable products.

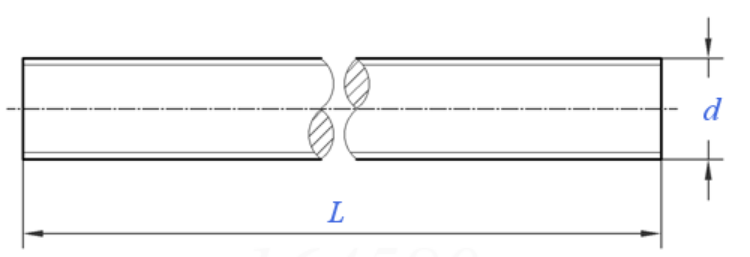

A heavy flat washer is typically made from durable materials such as steel, stainless steel, or plastic, designed to distribute the load of a fastener. This distribution helps prevent damage to the surface being fastened, reducing the risk of loosening and ensuring long-lasting performance. The manufacturing process of these washers involves several key stages, including material selection, cutting, forming, and surface treatment.

At the heart of a reputable heavy flat washers factory lies a commitment to quality. This commitment begins with the selection of premium materials. Factories often source their raw materials from trusted suppliers who meet stringent standards. Quality control measures are implemented at every stage to ensure that the washers produced are free of defects and meet specific industry requirements.

heavy flat washers factory

One of the defining features of an advanced factory is its use of state-of-the-art technology. Automated machinery and precision engineering allow for faster production rates and consistent quality. Advanced computer-aided design (CAD) software is employed to create detailed specifications, while computer numerical control (CNC) machines execute the manufacturing process with remarkable accuracy. These technologies enable factories to produce washers in various sizes and thicknesses, catering to the diverse needs of their clients.

Furthermore, a heavy flat washers factory must adhere to industry standards and certifications. Compliance with ISO and ASTM standards, for example, assures customers of the reliability and safety of the washers. Many factories also implement lean manufacturing principles, which enhance efficiency and reduce waste, allowing for environmentally friendly operations.

In addition to manufacturing prowess, strong customer service is a hallmark of a successful factory. Establishing lasting relationships with clients through open communication, customized solutions, and timely delivery increases customer satisfaction and loyalty.

In summary, the heavy flat washers factory plays a vital role in the manufacturing sector. By emphasizing quality control, leveraging advanced technology, adhering to industry standards, and prioritizing customer service, these factories ensure that they meet the demands of a competitive market. As industries continue to evolve, the importance of reliable components like heavy flat washers remains paramount, underscoring the need for exceptional manufacturing practices.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025