hdg hex bolts company

Nov . 16, 2024 21:24 Back to list

hdg hex bolts company

HDG Hex Bolts The Backbone of Modern Engineering

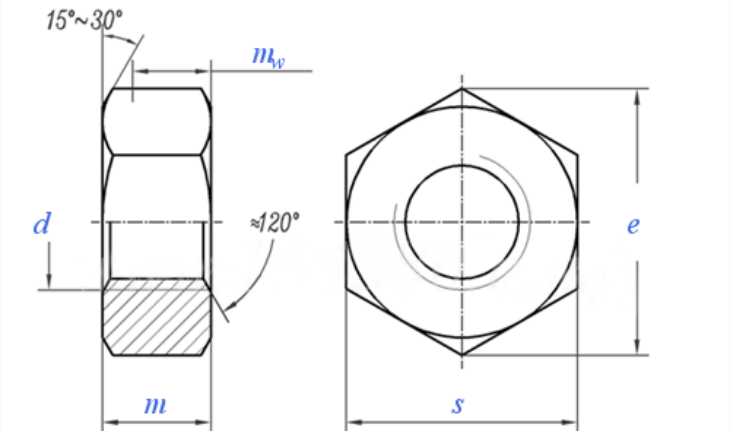

Hex bolts, often referred to as hexagonal bolts due to their distinctive six-sided heads, are crucial components in construction and engineering. When it comes to durability and corrosion resistance, hot-dip galvanized (HDG) hex bolts stand out in the marketplace. This article delves into the significance of HDG hex bolts, their manufacturing process, advantages, and typical applications, emphasizing why they are considered an essential choice for engineers and builders alike.

The Manufacturing Process

The production of HDG hex bolts begins with high-quality steel rods. The rods are cut into lengths that determine the final size of the bolts. After cutting, the bolts go through a process of threading and shaping to achieve the hexagonal head. Once the basic shape is formed, they are subjected to a rigorous quality inspection to ensure they meet the required standards for tensile strength and durability.

The HDG process itself involves immersing the cleaned hex bolts in molten zinc at temperatures around 450°C (842°F). This coating forms a strong metallurgical bond with the steel, producing a thick layer of zinc that protects the bolts from atmospheric corrosion. This method not only enhances the corrosion resistance of the bolts but also provides a robust barrier against rust, which is particularly important in harsh environments.

Benefits of HDG Hex Bolts

1. Corrosion Resistance The most significant advantage of HDG hex bolts is their enhanced resistance to corrosion. The zinc coating provides long-lasting protection against rust and degradation, particularly in environments exposed to moisture, salt, and chemicals.

2. Durability HDG hex bolts are engineered to withstand high loads and stress, making them suitable for heavy-duty applications. Their robust nature ensures that they can endure dynamic loads and vibrations, which are common in structural applications.

3. Cost-Effectiveness While the initial costs of HDG hex bolts may be higher than plain steel options, their longevity and reduced maintenance costs make them a smart investment over time. The need for replacements or repairs is significantly diminished, leading to overall savings in project budgets.

4. Ease of Installation The hexagonal shape of the bolt head allows for easy gripping with standard wrenches, facilitating quick and efficient installation. This user-friendly feature helps in reducing labor costs and time during construction and assembly processes.

hdg hex bolts company

5. Aesthetic Appeal The shiny, galvanized finish of HDG bolts not only improves their resistance to corrosion but also provides an aesthetic appeal that can be favorable in visible applications.

Typical Applications of HDG Hex Bolts

HDG hex bolts are widely used across various industries due to their superb properties. Some of the most common applications include

- Construction From residential buildings to large-scale commercial structures, HDG hex bolts are pivotal in securing beams, columns, and trusses. Their strength and resistance to environmental factors make them ideal for use in foundations and structural frames.

- Transportation In the automotive and aerospace sectors, HDG hex bolts are critical for assembling various components. Their durability ensures the safety and longevity of vehicles and aircraft.

- Manufacturing Many manufacturing processes rely on HDG hex bolts to assemble machinery and equipment. Their ability to withstand high stress and strain makes them essential in this sector.

- Marine Applications Given their excellent corrosion resistance, HDG hex bolts are often utilized in marine environments where exposure to saltwater can quickly deteriorate uncoated materials.

Conclusion

In conclusion, HDG hex bolts are not just another fastening option; they represent a vital component in the world of engineering and construction. With their remarkable corrosion resistance, durability, and cost-effectiveness, they are highly regarded in various industries. As construction techniques and environmental challenges evolve, the demand for reliable fastening solutions like HDG hex bolts continues to rise, defining the future of robust, sustainable engineering practices. Whether you are a builder, engineer, or DIY enthusiast, understanding the importance of these bolts can ensure your projects are built to last.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025