Exploring Manufacturers of GoPro Screws and Their Production Processes

Nov . 07, 2024 13:07 Back to list

Exploring Manufacturers of GoPro Screws and Their Production Processes

The Importance of GoPro Screws in the Action Camera Industry

GoPro has revolutionized the way we capture adventure and explore the world through its innovative range of action cameras. While much attention is given to the cameras themselves—their features, durability, and image quality—an often-overlooked aspect is the screws that hold these devices together. The significance of GoPro screws extends beyond mere functionality; they play a pivotal role in the design and usability of the entire camera system.

The Role of Screws in GoPro Cameras

Screws in GoPro cameras are not just simple fasteners; they serve multiple essential functions. Primarily, they ensure that the camera's body is tightly secured, providing protection for the sensitive electronics housed within. Given the nature of action sports and activities for which GoPro cameras are used—ranging from surfing to skydiving—the need for robustness in construction is paramount. The screws must withstand vibrations, shocks, and impacts while maintaining the integrity of the camera.

Moreover, screws allow for modularity and versatility. Many GoPro accessories, such as mounts, frames, and external microphones, require the use of screws for attachment. This modular design enables users to customize their setup based on the activity at hand, whether it be a thrilling bike ride or a serene underwater exploration. Without the right screws, the performance and adaptability of GoPro cameras would be severely limited.

Factories Specializing in GoPro Screws

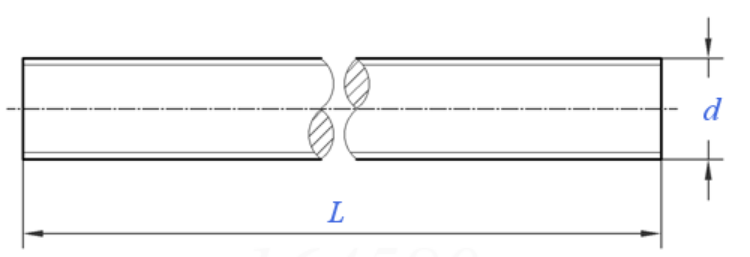

The manufacturing process of GoPro screws is as intricate as the devices they serve. Specialized factories produce these components using high-quality materials such as stainless steel, aluminum, and engineered plastics. The choice of material is crucial; it needs to withstand the elements while being light enough not to compromise the camera's portability—another hallmark of GoPro's design philosophy.

gopro screws factories

Factories dedicated to producing GoPro screws must adhere to stringent quality control measures. The screws must meet specific torque specifications and tolerances to ensure that they can endure the conditions faced by adventurous users. This is where advanced technology and precision engineering come into play. Many manufacturing units utilize CNC (Computer Numerical Control) machining to produce screws with high accuracy, ensuring consistency in size and function across all batches.

Sustainability and Innovation

As the demand for GoPro cameras continues to rise, so does the responsibility of factories to adopt sustainable practices. Many manufacturers are implementing eco-friendly processes in the production of GoPro screws, utilizing recycled materials whenever possible and minimizing waste. This is essential not only for environmental conservation but also as a response to growing consumer demand for sustainability in production.

Innovation in screw design is also an ongoing trend. Engineers are continually exploring new designs that enhance performance while reducing weight. For instance, innovations such as self-locking screws or screws with specialized coatings to resist corrosion are paving the way for improved durability and performance. These advancements contribute to the overall quality of GoPro products, ensuring users can capture their adventures without fear of equipment failure.

Conclusion

In conclusion, while GoPro cameras are celebrated for their cutting-edge technology and design, the screws that hold them together play an equally crucial role in their performance and usability. The factories that produce these screws are essential to the ecosystem of the action camera industry, focusing on quality, sustainability, and innovation. As the adventure continues and more consumers engage with GoPro products, the importance of these small yet significant components will only grow. So, the next time you capture a breathtaking moment with your GoPro, take a moment to appreciate the unsung hero—the screw—that helps make it all possible.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025