fine thread nuts

Nov . 04, 2024 22:59 Back to list

fine thread nuts

Exploring Fine Thread Nuts An Essential Component in Precision Engineering

Fine thread nuts are a critical component in the world of precision engineering, often overlooked in discussions about mechanical assemblies yet essential for ensuring the integrity and performance of various applications. With their unique characteristics and advantages, fine thread nuts play a significant role across multiple sectors, including automotive, aerospace, construction, and machinery.

Understanding Fine Thread Nuts

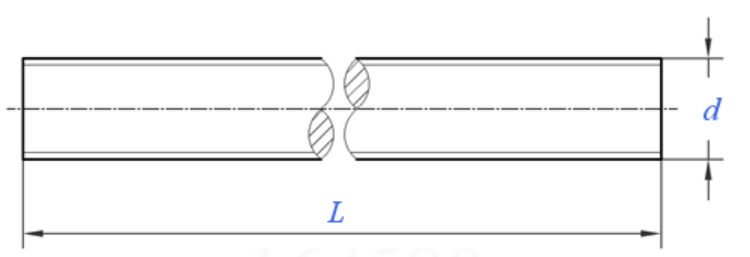

Fine thread nuts are designed to fit onto fine thread bolts and provide a secure fastening solution. The key difference between fine and coarse threads lies in the pitch—the space between the threads. Fine threads have a smaller pitch, which means more threads per inch, leading to a tighter grip as well as greater resistance to loosening under vibrational conditions. This makes fine thread nuts particularly advantageous in applications where stability and precision are paramount.

Advantages of Fine Thread Nuts

1. Increased Strength and Durability The tighter engagement of fine threads increases the load-bearing capacity of the connection. Fine thread nuts are less likely to strip, making them ideal for high-stress environments. They also tend to exhibit better performance when exposed to fatigue and thermal cycling.

2. Improved Adjustability Fine threads offer superior adjustments and precision in applications where minute movements are necessary. This is especially important in machinery settings where exact alignment can affect overall functionality.

3. Resistance to Loosening The increased number of threads in fine thread nuts enhances friction, which in turn reduces the likelihood of loosening due to vibrations. This feature is particularly vital in automotive and aerospace applications, where safety and reliability are critical.

fine thread nuts

4. Versatility and Range of Materials Fine thread nuts come in various materials, including steel, stainless steel, brass, and nylon, allowing for their use in a wide array of environments and applications. The choice of material can influence the nut's corrosion resistance, strength, and weight.

Applications in Different Industries

Fine thread nuts are utilized across a variety of sectors, highlighting their versatility. In the automotive industry, they are used in assembling engines and suspension systems where precise torque is necessary for optimal performance. In aerospace, fine thread nuts secure critical components in aircraft, ensuring safety and reliability at high altitudes and variable temperatures.

In construction, these nuts provide strength in structural applications, securing heavy machinery and equipment where vibrations are common. Moreover, in machinery, fine thread nuts are found in precision instruments and robotic systems, where their ability to retain tight tolerances is essential.

Installation and Best Practices

Installing fine thread nuts requires attention to detail. It is crucial to ensure that the threads of both the nut and bolt are clean and free from debris to prevent cross-threading. Utilizing the appropriate torque specifications during installation is vital, as overtightening can lead to stripping or breaking of the bolt, while under-tightening can compromise connection integrity.

Conclusion

In conclusion, fine thread nuts are indispensable components in modern engineering and manufacturing. Their unique features provide enhanced security, precision, and durability, making them suitable for an array of critical applications. As industries continue to evolve and demand higher performance standards, the importance of fine thread nuts will only grow, solidifying their role in the future of mechanical design and assembly. Understanding their benefits and applications is crucial for anyone involved in engineering and manufacturing, paving the way for innovations and advancements in technology.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025