famous saberdrive screws

Nov . 11, 2024 19:17 Back to list

famous saberdrive screws

The Evolution of Famous Saber Drive Screws A Mechanical Marvel

Screws, although small in size, play a pivotal role in the mechanics of countless devices and structures. Among the myriad of screw designs, saber drive screws have emerged as a noteworthy innovation, revered for their efficiency and versatility. This article delves into the development, applications, and advantages of saber drive screws, showcasing their significance in contemporary engineering.

The Genesis of Saber Drive Screws

The saber drive screw was introduced as a response to the increasing need for more efficient fastening solutions. Traditional screws often faced challenges such as slippage and difficulty in achieving a strong grip, particularly under high torque conditions. As the demand for more robust and reliable fastening options grew, engineers and designers began to explore alternatives.

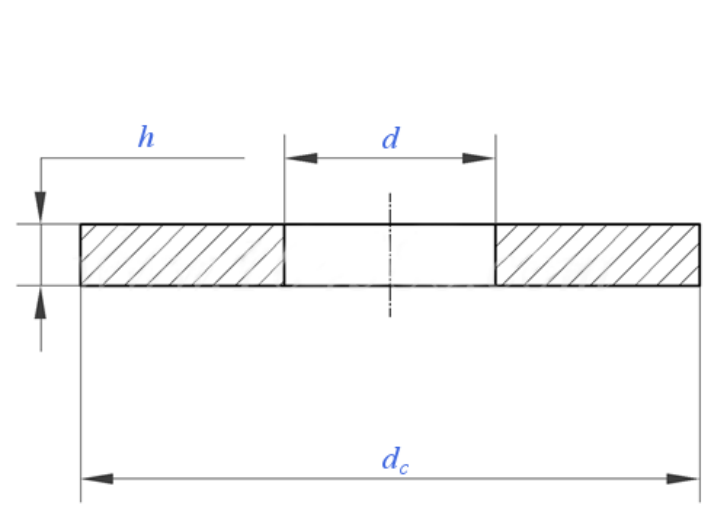

The saber drive system features a unique head design, which incorporates a series of notches or indentations that allow for greater torque transfer. This innovation provides a secure fit with a specialized driver tool, which is designed to match the shape of the screw head precisely. This compatibility drastically reduces the chances of stripping, thereby enhancing the longevity of both the screw and the driver itself.

Features and Design

One of the key attributes of saber drive screws is their distinct head design. Typically characterized by a star or multiple-point configuration, this design allows for better engagement with the driver tool. One significant aspect of this design is the “saber” profile, offering more surface area compared to conventional screw heads. This translates to a more efficient torque transfer, leading to higher tightening capabilities without the risk of damaging the screw.

Additionally, saber drive screws often come with a variety of coatings and materials, making them suitable for diverse environments. From corrosion-resistant finishes to high-strength alloys, these screws can be tailored to meet specific industrial requirements. This adaptability further solidifies their place as a preferred choice in various applications.

Applications of Saber Drive Screws

famous saberdrive screws

The use of saber drive screws spans multiple industries, demonstrating versatility and reliability. In the automotive sector, for instance, these screws are employed in assembling crucial components such as engines and chassis. Their ability to withstand high torque and provide a secure fit ensures the safety and performance of vehicles on the road.

Similarly, in the manufacturing and construction sectors, saber drive screws are prevalent in both heavy and light-duty applications. They are used in framing, cabinetry, and structural assemblies, where the integrity of the fastening solution is paramount. The aerospace industry has also shown interest in these screws due to their weight-to-strength ratio, which is critical in aircraft design where every gram counts.

Advantages of Saber Drive Screws

One of the primary advantages of saber drive screws is their resistance to cam-out, which is a common issue with traditional screw heads. This property not only enhances the ease of use during installation but also minimizes the risk of damage to both the screw and the surrounding material. As a result, projects require less maintenance and rework, saving both time and costs.

Moreover, the efficiency of saber drive screws allows for faster assembly processes. With reduced stripping and enhanced torque transfer, construction and manufacturing timelines can be significantly shortened, which is crucial in today’s fast-paced industries.

Furthermore, the customizable nature of saber drive screws, in terms of size, design, and material, empowers engineers to choose the best-suited fastening solution for their specific applications. This level of customization ensures that the screws can withstand the operational stresses they are subjected to, making them a dependable choice across various applications.

Conclusion

In conclusion, the saber drive screw represents a remarkable advancement in fastening technology, merging innovation with functionality. Its unique design and robust performance have positioned it as a critical component in various fields, from automotive to aerospace. As engineering continues to evolve, it is likely that the saber drive screw will adapt alongside, solidifying its status as an integral part of modern mechanical design. With ongoing advancements and applications, the legacy of saber drive screws is bound to expand, paving the way for future innovations in the world of fasteners.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025