famous m30 stud bolt

Nov . 06, 2024 05:31 Back to list

famous m30 stud bolt

The Famous M30 Stud Bolt A Key Component in Engineering

In the world of engineering and construction, the significance of reliable fastening systems cannot be overstated. Among the myriad of fasteners available, the M30 stud bolt stands out as a key component that offers strength, durability, and versatility. With its unique characteristics, the M30 stud bolt has become a favorite among engineers and builders alike, serving as a backbone in various applications, from heavy machinery to structural assemblies.

What is an M30 Stud Bolt?

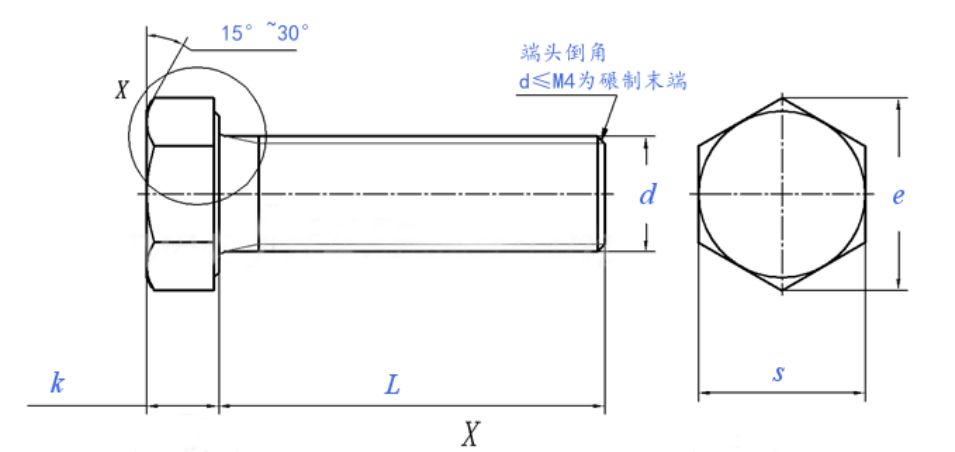

The M30 stud bolt is a cylindrical rod that features a threading along its length. Typically, the “M” in M30 denotes the metric system, indicating that the bolt has a diameter of 30 millimeters. As a stud bolt, it is designed for use in conjunction with nuts and washers, providing an effective means of joining two or more objects securely. The M30 size allows for substantial load-bearing capacity, which is crucial in many industrial applications.

Applications of M30 Stud Bolts

One of the primary uses of M30 stud bolts is in heavy machinery and equipment assemblies. For instance, they are often used to secure components in engines, where high tensile strength is vital to withstand vibrations and stresses. In construction, M30 stud bolts are employed to fasten steel beams, reinforcing structures in high-rise buildings and bridges with exceptional stability. Additionally, the oil and gas industry frequently utilizes M30 stud bolts in flange connections, ensuring that pipelines are sealed tightly and can withstand high-pressure environments.

Materials and Finishes

famous m30 stud bolt

The material choice for M30 stud bolts is paramount, as it affects the bolt's strength, corrosion resistance, and overall longevity. Common materials include carbon steel, stainless steel, and alloy steel, each selected based on the specific requirements of the application. For instance, stainless steel M30 studs are favored in corrosive environments, such as coastal regions or chemical processing plants, due to their superior resistance to rust and decay.

Moreover, finishes applied to M30 stud bolts can enhance their performance. Galvanization, for example, involves coating the bolt with zinc to provide an additional layer of protection against corrosion. Other finishes may include black oxide or powder coating, which not only improve resistance to harsh conditions but also offer aesthetic appeal.

Installation and Maintenance

Proper installation of M30 stud bolts is crucial for ensuring that they perform as intended. The use of torque wrenches during installation can help achieve the necessary tension, preventing common issues such as loosening due to vibration. Regular inspections and maintenance are also important; checking for signs of wear, corrosion, or fatigue ensures longevity and reliability. In case of damage, timely replacement can avert potential failures that could lead to significant safety hazards.

Conclusion

The M30 stud bolt has proven itself to be an indispensable component in various fields, offering unmatched strength and adaptability. Whether in critical engineering applications or everyday construction projects, its reliability contributes to the integrity and safety of structures worldwide. As industries continue to evolve, the M30 stud bolt remains a symbol of modern engineering's commitment to quality and performance, embodying the ideals of precision and durability essential in today's fast-paced world.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025