Exploring the Features and Benefits of the Famous DIN 2510 Stud Bolt in Engineering Applications

Aug . 07, 2024 20:05 Back to list

Exploring the Features and Benefits of the Famous DIN 2510 Stud Bolt in Engineering Applications

The Importance of the Famous DIN 2510 Stud Bolt in Engineering Applications

In the world of engineering and mechanical design, quality fasteners are essential components that ensure the reliability and safety of structures and machinery. Among these fasteners, the DIN 2510 stud bolt holds a significant place due to its robust design and application versatility. As industrial needs have evolved over the years, so has the standardization of components like the DIN 2510 stud bolt, which adheres to rigorous specifications that enhance its performance in various environments.

What is a DIN 2510 Stud Bolt?

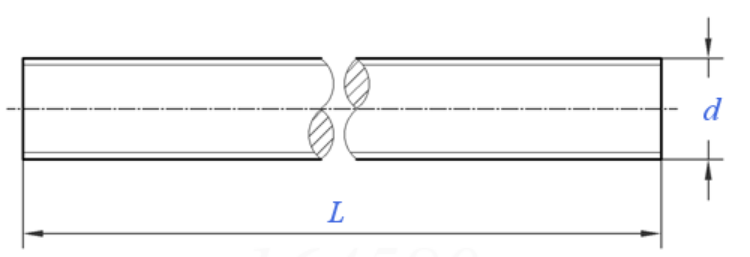

The DIN 2510 stud bolt is a type of fastener specifically designed for use in high-stress applications, particularly those that require substantial tensile strength. It is characterized by its double-ended design, which consists of a cylindrical rod with threads on either end. This structure allows it to be utilized in both tension and compression applications, making it an ideal choice for connecting two parts of machinery or other structural elements.

The term DIN refers to the Deutsches Institut für Normung, a German standards organization that sets quality and performance benchmarks for various components. The DIN 2510 standard outlines specific dimensions and material properties for stud bolts, ensuring consistency and quality across different manufacturers. This standardization is crucial in engineering applications, where the failure of a single component can lead to significant safety hazards or operational failures.

Applications of DIN 2510 Stud Bolts

DIN 2510 stud bolts are widely used in various sectors, including construction, automotive, aerospace, and manufacturing. In these industries, robust fastening solutions are essential for maintaining structural integrity and ensuring equipment functionality.

1. Automotive Industry In vehicles, DIN 2510 stud bolts are employed in the assembly of engines, exhaust systems, and suspension components. Their ability to withstand vibrations and thermal cycling makes them perfect for such demanding applications.

famous din 2510 stud bolt

2. Construction For building structures, these stud bolts are frequently used in steel frames, where they provide reliable connections between beams and columns. Their high tensile strength allows them to handle loads effectively, ensuring the safety and stability of the structure.

3. Aerospace Engineering The aerospace sector relies on high-quality fasteners like the DIN 2510 for assembling aircraft components. Given the extreme conditions faced during flight, including fluctuations in temperature and pressure, the durability and reliability of stud bolts are paramount.

4. Manufacturing In various manufacturing processes, DIN 2510 stud bolts are utilized to secure machinery, ensuring that all parts remain aligned under operational stress. Their resistance to fatigue makes them ideal for applications involving continuous motion or heavy loads.

Material and Strength Considerations

The performance of a DIN 2510 stud bolt significantly depends on its material composition. Usually made from carbon steel, stainless steel, or alloy steel, the choice of material will influence its corrosion resistance, tensile strength, and overall durability. For instance, stainless steel stud bolts are advisable in environments exposed to moisture and chemicals, while carbon steel may suffice in dry conditions where high tensile strength is required.

Moreover, the mechanical properties of the stud bolt, such as yield strength and tensile strength, are meticulously defined in the DIN 2510 standard. It ensures that engineers can select the proper size and material for their specific application, thus preventing potential failures.

Conclusion

In summary, the DIN 2510 stud bolt is an essential fastener in many engineering applications, offering versatility, strength, and reliability. By adhering to standardized dimensions and material specifications, manufacturers can ensure that these stud bolts meet the high-performance expectations of various industries. As technology advances and engineering challenges evolve, the DIN 2510 stud bolt is likely to remain a cornerstone in fastener design, ensuring safe and efficient operations across multiple applications.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025