Exploring Leading Companies Specializing in Battery Stud Bolts and Their Innovative Solutions

Aug . 15, 2024 15:50 Back to list

Exploring Leading Companies Specializing in Battery Stud Bolts and Their Innovative Solutions

The Importance of Battery Stud Bolts in Energy Storage Solutions

In the rapidly evolving landscape of energy storage solutions, battery technology plays a crucial role in the efficiency and effectiveness of various applications, from electric vehicles to renewable energy systems. One often-overlooked component in this technology is the battery stud bolt, which serves both functional and structural purposes in battery assembly. In this article, we will explore the significance of battery stud bolts, their manufacturing companies, and their role in maintaining the integrity of battery systems.

What Are Battery Stud Bolts?

Battery stud bolts are specialized fasteners that are essential for the assembly and connection of battery cells in various configurations. These bolts are designed to withstand high levels of stress and ensure the secure attachment of terminals and other critical components. With their robust construction, battery stud bolts help mitigate the risk of connection failure, which can lead to energy loss, performance issues, or even catastrophic failures in battery systems.

The Role of Battery Stud Bolt Companies

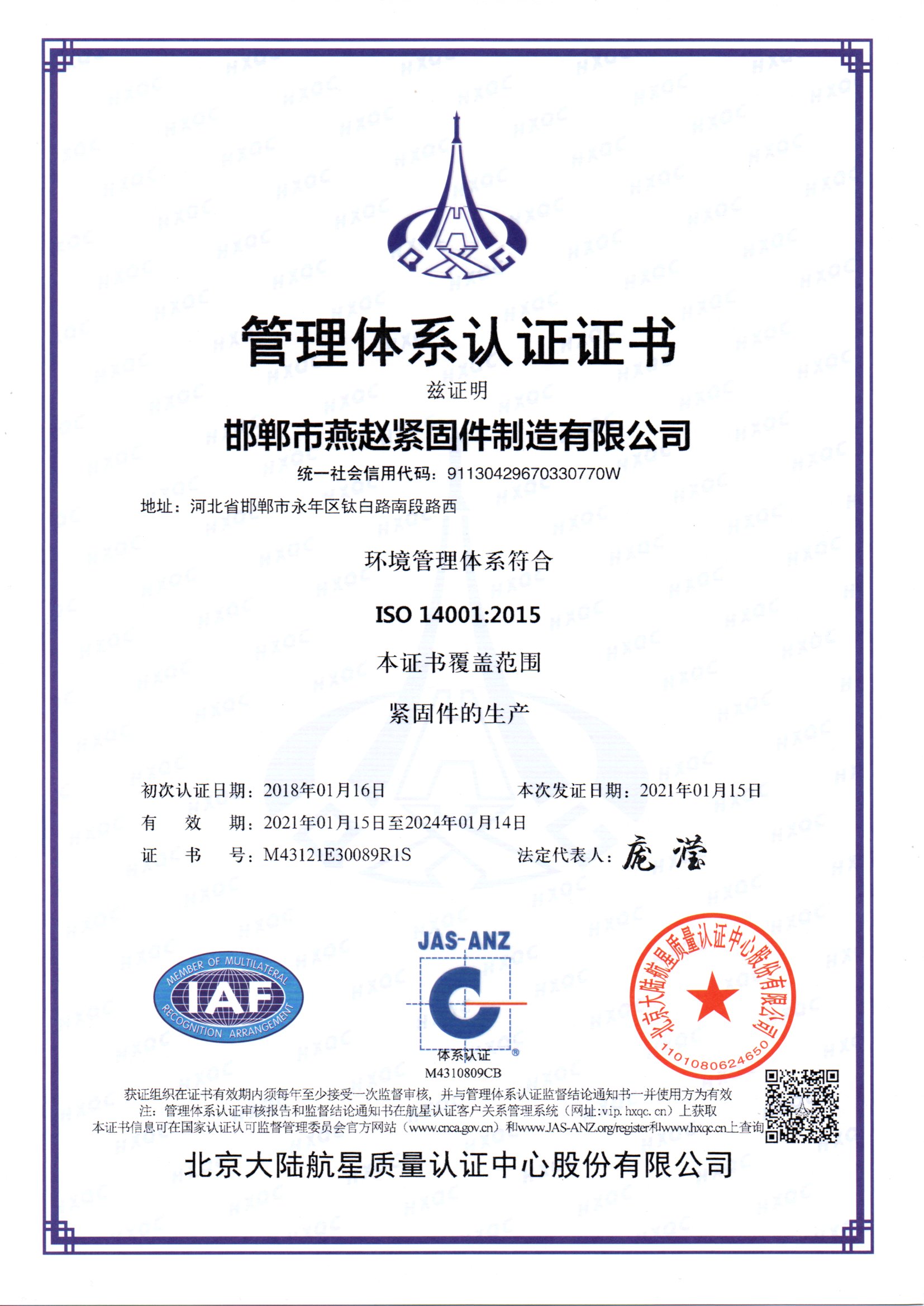

As the demand for improved energy storage systems continues to grow, the market for battery stud bolts has expanded significantly. Numerous companies specialize in manufacturing these fasteners, focusing on quality, durability, and reliability. These companies utilize advanced materials, such as stainless steel and specialty alloys, to produce bolts that can withstand extreme temperatures, vibrations, and corrosive environments typical in battery applications.

Leading manufacturers prioritize the development of high-performance battery stud bolts, often employing the latest technologies in production and testing. They also adhere to strict industry standards to ensure their products meet safety and efficacy requirements. Many of these companies are involved not only in the production of battery stud bolts but also in providing comprehensive solutions for battery assembly. This includes offering consulting services to optimize bolt selection, installation, and maintenance practices.

battery stud bolt companies

Innovations and Trends in Battery Stud Bolt Manufacturing

As the energy storage market continues to innovate, battery stud bolt manufacturers are also exploring new designs and materials to enhance performance. Recent trends include the development of bolts with improved corrosion resistance, the use of lightweight materials to reduce overall weight in applications like electric vehicles, and innovations in thread design for better electrical conductivity.

Additionally, some manufacturers are investing in automation and advanced manufacturing techniques to improve the consistency and precision of their products. By leveraging technologies such as 3D printing and computer-aided design (CAD), these companies can create custom fasteners tailored to specific battery architectures, thereby enhancing the overall efficiency of the energy storage solution.

The Future of Battery Stud Bolts

The role of battery stud bolts will only become more critical as the shift toward renewable energy and more efficient energy storage solutions accelerates. As electric vehicles and large-scale energy storage systems become more mainstream, the demand for reliable and high-quality fastening solutions will continue to rise.

In conclusion, battery stud bolts may be small components in the grand scheme of battery technology, but they are pivotal in ensuring reliability and safety in energy storage systems. Companies specializing in their production play an essential role in the advancement of battery technology, contributing significantly to the industry's overall growth. As innovations continue to unfold, the effective design and manufacturing of battery stud bolts will remain crucial for meeting the demands of an ever-evolving energy landscape. Investing in high-quality bolts from reputable manufacturers is a wise decision for anyone involved in the energy storage sector, ensuring both operational success and safety in their applications.

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025