E46 Engine Valve Cover Stud Bolt Specifications and Installation Guide for Optimal Performance

Jul . 30, 2024 01:23 Back to list

E46 Engine Valve Cover Stud Bolt Specifications and Installation Guide for Optimal Performance

Understanding the E46 Valve Cover Stud Bolt Factory

The BMW E46, part of the 3 Series produced between 1997 and 2006, is widely regarded for its engineering excellence and driving dynamics. One critical component in maintaining the engine's integrity is the valve cover, secured by a series of stud bolts. Understanding the significance of these valve cover stud bolts and the manufacturing processes behind them can offer insightful perspectives on automotive engineering and maintenance.

The Role of Valve Cover Stud Bolts

Valve cover stud bolts play an essential role in the overall functioning of the engine. They secure the valve cover to the cylinder head, ensuring that the engine oil remains contained and that no contaminants enter the combustion chamber. Moreover, a properly sealed valve cover prevents leaks, preserving engine performance and efficiency. Over time, vibrations, heat cycles, and exposure to engine oil can lead to wear and tear on these bolts, making regular inspection and replacement a crucial aspect of vehicle maintenance.

Manufacturing Processes

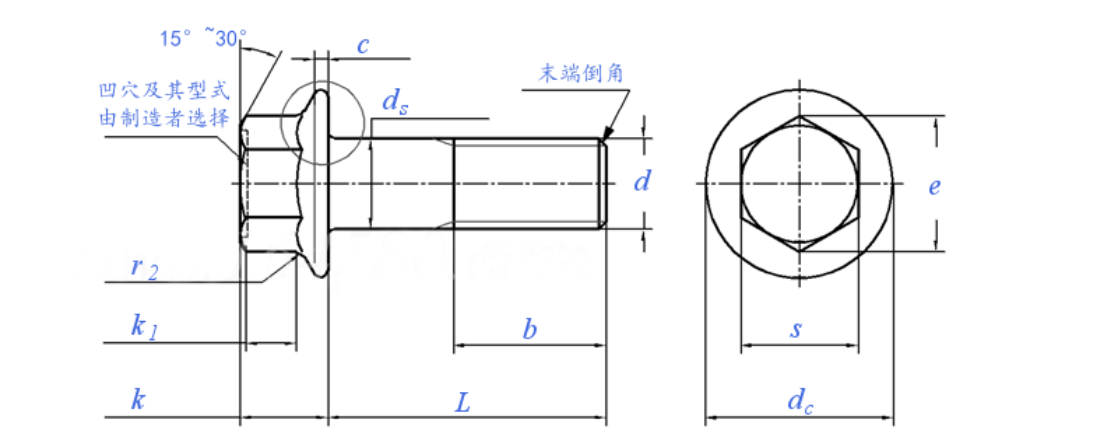

The manufacturing of valve cover stud bolts involves several stages, ensuring both durability and reliability. Typically, these bolts are crafted from high-strength materials, such as steel alloys, which can withstand the harsh conditions of an automotive environment. The fabricating process starts with the selection of raw materials, which are then subjected to forging or machining processes to achieve the required dimensions and strength.

Once forged, the bolts undergo heat treatment to enhance their hardness and tensile strength. This process is vital, as it ensures that the bolts can handle the significant stress and pressure exerted on them during operation. After heat treatment, the bolts are usually coated with anti-corrosive materials to protect them from rust and degradation, which can be particularly prevalent in automotive applications.

e46 valve cover stud bolt factory

Quality control is a critical aspect of manufacturing at the E46 valve cover stud bolt factory. Each batch of bolts is rigorously tested for compliance with industry standards. This involves checking the dimensional accuracy, hardness, and tensile strength of the finished product to ensure reliability and performance. Such meticulous attention to detail guarantees that the final product meets the specific requirements essential for the BMW E46 engine.

Maintenance and Replacement

While the E46 is known for its reliability, routine maintenance is pivotal to ensuring the longevity of its components, including the valve cover stud bolts. Mechanics often recommend inspecting these bolts during significant maintenance intervals, especially when addressing valve cover gasket leaks or performing head gasket replacements.

If you discover that the stud bolts are loose, corroded, or stripped, replacing them promptly is vital to preventing engine oil leaks and maintaining optimal engine performance. When replacing these bolts, it is essential to follow the manufacturer's specifications for torque settings to avoid over-tightening, which can lead to further complications.

Conclusion

The E46 valve cover stud bolts are small components with a significant role in BMW's renowned engineering prowess. Understanding their manufacturing processes and maintenance implications can enhance the appreciation of automotive design and performance. Recognizing the importance of these bolts can lead to better vehicle care and ensure the continued reliability of a beloved classic like the BMW E46. Through regular inspections and appropriate replacements, owners can enjoy many more miles of driving pleasure, fully aware of the intricate details that keep their engines running smoothly.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025