Duplex Screws Manufacturers and Exporters for Quality Fastening Solutions Worldwide

Nov . 29, 2024 10:24 Back to list

Duplex Screws Manufacturers and Exporters for Quality Fastening Solutions Worldwide

The Growing Market of Duplex Screws Exporters

In the ever-evolving landscape of manufacturing and construction, duplex screws have emerged as a crucial component that offers exceptional strengths and corrosion resistance. These screws, made from a combination of austenitic and ferritic stainless steel, are particularly favored for their ability to withstand harsh environments while maintaining structural integrity. As global demand for high-quality fasteners continues to surge, the role of duplex screws exporters becomes increasingly significant. This article explores the factors driving the growth of this sector, the challenges faced by exporters, and the future prospects of duplex screw trade.

What are Duplex Screws?

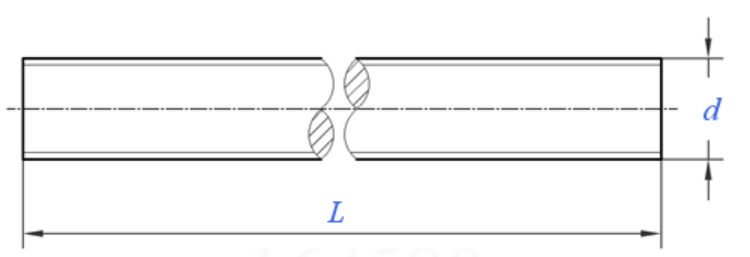

Duplex screws are specialized fasteners known for their unique composition of stainless steel, which combines the best qualities of both austenitic and ferritic types. This dual-phase structure grants them enhanced strength, excellent resistance to pitting, and corrosion in saline environments, making them ideal for a variety of industries, including marine, chemical processing, and construction. Their ability to perform under extreme conditions has also positioned them as essential components in the production of offshore oil rigs, bridges, and high-rise buildings.

Drivers of Demand

The increasing preference for duplex screws can be attributed to several factors. Firstly, the global push for infrastructure development has led to heightened demand in construction and engineering sectors. Countries are investing heavily in infrastructure projects, which requires durable and reliable fasteners. Additionally, the shift towards sustainable materials has resulted in a growing interest in duplex stainless steel, which is both recyclable and offers longevity compared to traditional materials.

Secondly, industries such as oil and gas, marine, and chemical production must contend with harsh and corrosive environments. Duplex screws provide the ideal solution, as they can resist the adverse effects of these conditions, leading to lower maintenance costs and longer service life. The increasing focus on safety and reliability in these sectors further fuels the demand for high-quality fasteners.

The Role of Exporters

Duplex screws exporters play a crucial role in bridging manufacturers and end-users across the globe. These exporters are responsible for understanding market trends, regulatory requirements, and the specific needs of various industries. By sourcing high-quality products and ensuring compliance with international standards, exporters can facilitate smoother transactions between producers and users.

duplex screws exporters

In recent years, many countries have seen a surge in the number of duplex screw manufacturers. This growth has fostered a competitive environment that encourages innovation and quality improvements. Exporters often collaborate with these manufacturers to provide customized solutions tailored to specific client needs.

Challenges Faced by Exporters

Despite the opportunities, duplex screws exporters also face several challenges in the marketplace. One major hurdle is the fluctuating prices of raw materials, particularly nickel and molybdenum, which are essential components of duplex stainless steel. These fluctuations can impact production costs, leading to unpredictable pricing for exporters.

Additionally, exporters must navigate complex international shipping regulations and customs requirements. Ensuring timely delivery while adhering to these regulations can strain logistics and supply chain operations. Furthermore, the growing need for sustainable practices means that exporters must also consider environmental regulations and labeling requirements, which can add to their operational burden.

Future Prospects

The future of duplex screws exporters looks promising. As industries continue to evolve and emphasize innovation and sustainability, the demand for corrosion-resistant fasteners is expected to remain strong. The growth of emerging markets, coupled with increased investments in infrastructure projects globally, creates ample opportunities for exporters.

Moreover, technological advancements in manufacturing processes, such as additive manufacturing and improved metallurgy, could lead to even more enhanced duplex screw products. Exporters who are willing to adapt and integrate these technologies into their offerings will likely gain a competitive edge.

In conclusion, the duplex screws export market illustrates a dynamic landscape driven by global industrial demands and material advancements. The role of exporters in connecting manufacturers with various industries is vital to meeting the growing need for reliable fasteners. While challenges exist, the overall outlook remains positive as the world continues to recognize the importance of durable, high-performance materials in ensuring safety and efficiency in construction and manufacturing.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025