custom washer for bolts and nuts

Nov . 02, 2024 08:41 Back to list

custom washer for bolts and nuts

Custom Washers for Bolts and Nuts Essential Fastening Components

In the world of mechanical engineering and construction, the importance of every component cannot be overstated, and custom washers for bolts and nuts are no exception. While they may seem like simple pieces of hardware, washers play a critical role in a variety of applications, from machinery and automotive to construction and household repairs. Understanding the significance of custom washers can ensure that projects not only meet specifications but also perform reliably over time.

What Are Washers and Why Are They Important?

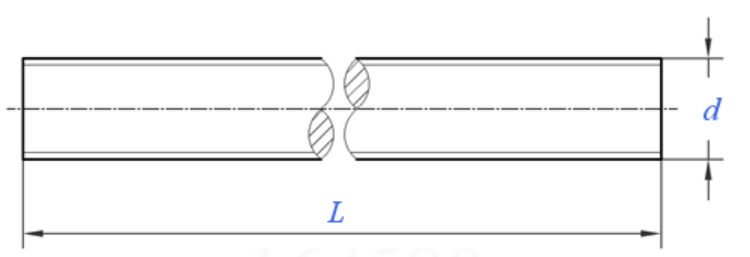

Washers are thin, flat disks made from materials such as metal, plastic, or rubber. They are placed between a bolt or nut and the surface of the material being fastened. Their primary functions are to distribute load, reduce vibration, prevent leakage, and protect surfaces from damage. In situations where a bolt or nut is fastened to a softer material, washers can prevent the fastener from embedding into the substrate, thereby maintaining the integrity of the assembly.

The customization of washers is crucial when standard washers do not fulfill unique application requirements. Various factors such as size, shape, material, and thickness can significantly influence the performance of the fastening system. Custom washers can be designed to suit specific tolerances, ensuring optimal fit and function.

Applications of Custom Washers

1. Automotive Industry In automotive applications, custom washers are vital for securing components subjected to harsh conditions. For instance, specialty washers can be designed to resist high temperatures or chemical exposure in engine assemblies.

2. Aerospace In aerospace engineering, every component must adhere to strict safety regulations. Custom washers can be produced from lightweight, high-strength materials to reduce overall weight while ensuring structural integrity.

custom washer for bolts and nuts

3. Construction In construction, custom washers are often needed for securing beams and other structural components. They can be produced to accommodate unique bolt sizes or load requirements, enhancing the overall safety of the structure.

4. Electronics In electronic devices, custom washers can prevent short circuits. By isolating electrical connections, they help in maintaining operational efficiency and prolonging the lifespan of the equipment.

Benefits of Using Custom Washers

The primary benefit of custom washers is their ability to meet specific requirements that off-the-shelf products may not satisfy. Custom manufacturing allows for precise specifications, which can enhance performance, reduce maintenance issues, and ultimately lower costs.

Additionally, custom washers can improve assembly efficiency. When washers are tailored to fit particular bolts or nuts, it minimizes the risk of installation errors, ensuring that the entire assembly process is more streamlined.

Conclusion

Custom washers for bolts and nuts may be small components, but they hold significant value in various industries. By understanding their importance and capabilities, engineers and manufacturers can make informed decisions that enhance the performance and reliability of their projects. Whether it’s making machinery more efficient, ensuring safety in aerospace applications, or enhancing structural integrity in construction, the role of custom washers is undeniably crucial in modern engineering practices. Investing in custom manufacturing can lead to improved functionality and longevity of the products, ultimately paving the way for innovation and excellence in multiple sectors.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025