High-performance Titanium Stem Bolts for Custom Bike Builds and Upgrades

Sep . 28, 2024 23:36 Back to list

High-performance Titanium Stem Bolts for Custom Bike Builds and Upgrades

Exploring the Benefits of Custom Titanium Stem Bolts

In the ever-evolving world of engineering and manufacturing, the demand for high-performance materials has reached new heights. Among these materials, titanium stands out for its exceptional strength, lightweight properties, and corrosion resistance, making it an ideal choice for critical applications. One area where titanium truly shines is in the realm of custom stem bolts used in various industries, including automotive, aerospace, and bicycle manufacturing.

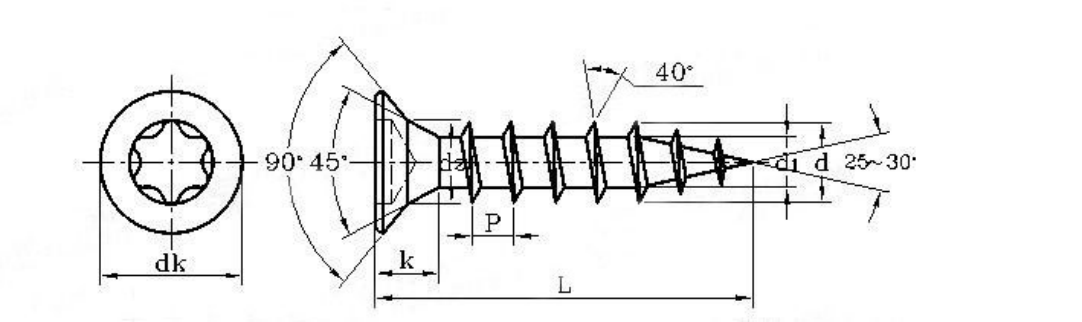

Custom titanium stem bolts are fasteners specifically designed to meet the unique requirements of a project or application. Unlike standard bolts, which come in predefined sizes and specifications, custom bolts can be tailored in terms of dimensions, threading, and other characteristics. This customization is essential, as it allows engineers and designers to optimize components for performance, durability, and aesthetic appeal.

One of the primary advantages of titanium is its strength-to-weight ratio. Titanium is about 45% lighter than steel but possesses nearly the same tensile strength, which means that engineers can use smaller, lighter bolts without compromising on durability or load-bearing capacity. This is particularly advantageous in the aerospace and automotive industries, where every gram matters. By incorporating custom titanium stem bolts, manufacturers can reduce the overall weight of their products, leading to improved fuel efficiency and performance.

Corrosion resistance is another critical factor that makes titanium a preferred material. Unlike steel, which can rust and degrade when exposed to moisture and harsh environments, titanium naturally forms a protective oxide layer that shields it from corrosion. This property is highly beneficial in applications where exposure to the elements is a concern, such as marine engineering or outdoor equipment. By using custom titanium stem bolts, companies can enhance the longevity of their products, minimizing the need for maintenance and replacement over time.

custom titanium stem bolts

Furthermore, titanium's biocompatibility makes it an ideal choice for medical applications. Custom titanium stem bolts are often used in prosthetics and orthopedic implants, where the bolts must withstand significant stress and strain while also being safe for human use. The ability to customize these fasteners ensures that they meet rigorous medical standards, providing both functionality and safety for patients.

The aesthetic appeal of titanium should not be overlooked either. Available in a range of colors and finishes, custom titanium stem bolts can significantly enhance the visual appeal of a product. In the cycling industry, for example, custom titanium bolts not only provide functional benefits but also contribute to the overall stylish design of high-end bicycles. This combination of form and function is increasingly sought after by consumers who value both performance and aesthetics in their purchases.

Moreover, advancements in manufacturing technologies, such as additive manufacturing (3D printing), have made it easier and more cost-effective to produce custom titanium stem bolts. With these technologies, it is possible to create intricate designs and geometries that were previously unattainable with traditional manufacturing methods. This flexibility allows engineers to innovate and design more complex components that can lead to improved performance and new possibilities in product design.

In conclusion, custom titanium stem bolts present a myriad of benefits across various industries. Their lightweight yet strong nature, excellent corrosion resistance, biocompatibility, aesthetic flexibility, and adaptability to modern manufacturing techniques make them a top choice for engineers and manufacturers. As industries continue to push for higher performance standards and innovative solutions, the demand for custom titanium components will undoubtedly grow, paving the way for a future where engineering and design excellence go hand in hand. Whether in aerospace, automotive, or medical fields, the rise of custom titanium stem bolts marks an exciting development in the quest for advanced materials and technologies.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025