custom sae bolts

Oct . 20, 2024 15:17 Back to list

custom sae bolts

Understanding Custom SAE Bolts A Comprehensive Guide

In the world of manufacturing and construction, fasteners play a critical role in ensuring the integrity and durability of structures and products. Among these, SAE (Society of Automotive Engineers) bolts are highly regarded for their strength and reliability. This article explores the concept of custom SAE bolts, highlighting their importance, applications, and advantages in various industries.

What Are SAE Bolts?

SAE bolts are standardized fasteners that adhere to the specifications set forth by the Society of Automotive Engineers. These bolts are designed to meet specific dimensional requirements, including diameter, length, and thread pitch. They are often made from various materials, including carbon steel, stainless steel, and alloy steel, which can be treated for enhanced strength and corrosion resistance.

The Importance of Custom SAE Bolts

While standard SAE bolts are sufficient for many applications, custom SAE bolts are essential when projects demand unique dimensions, specialized materials, or specific performance characteristics. Customization allows engineers and manufacturers to tailor fasteners to meet specific performance requirements, ensuring that they align with the unique needs of a project.

1. Precision Engineering Custom SAE bolts are designed to meet precise specifications that standard bolts cannot accommodate. This precision is critical in applications where structural integrity is paramount, such as in aerospace, automotive, and construction industries.

2. Enhanced Performance In specialized applications, the material properties of standard SAE bolts may not suffice. Custom SAE bolts can be manufactured from advanced materials or treated to withstand extreme conditions, such as high temperatures, corrosive environments, or heavy loads.

3. Improved Fit and Functionality Customization can also address fitment issues that arise in complex assemblies. Engineers may require bolts that fit into tight spaces or align with specific components in innovative designs. Custom SAE bolts can solve these challenges, promoting seamless assembly and enhancing overall functionality.

4. Cost-Effectiveness While custom components can sometimes be more expensive initially, they can lead to cost savings in the long run. Tailored solutions can improve the efficiency of assembly processes, reduce the likelihood of product failures, and minimize maintenance costs.

Applications of Custom SAE Bolts

Custom SAE bolts find their applications in various industries due to their versatility and reliability. Here are a few prominent examples

custom sae bolts

- Automotive Industry In the automotive sector, custom SAE bolts are used extensively in assembling vehicles. From securing engine components to attaching body panels, these fasteners must meet high-performance standards to ensure safety and reliability.

- Aerospace Industry The aerospace industry requires fasteners that can withstand extreme conditions, including high altitude and pressure variations. Custom SAE bolts are designed to meet stringent regulations and performance benchmarks essential for aviation safety.

- Construction Custom SAE bolts are critical in construction applications where unique structural requirements are present. These bolts help secure heavy machinery, support structural frameworks, and withstand significant physical stress.

- Manufacturing In various manufacturing processes, custom SAE bolts are used to meet specific assembly needs. Industries producing specialized equipment may require unique designs to ensure that their machinery operates efficiently and safely.

Choosing the Right Manufacturer

When considering custom SAE bolts, selecting the right manufacturer is crucial. Here are a few factors to keep in mind

1. Experience and Expertise Choose a manufacturer with extensive experience in designing and producing custom fasteners. Their expertise will ensure that your specifications are met accurately.

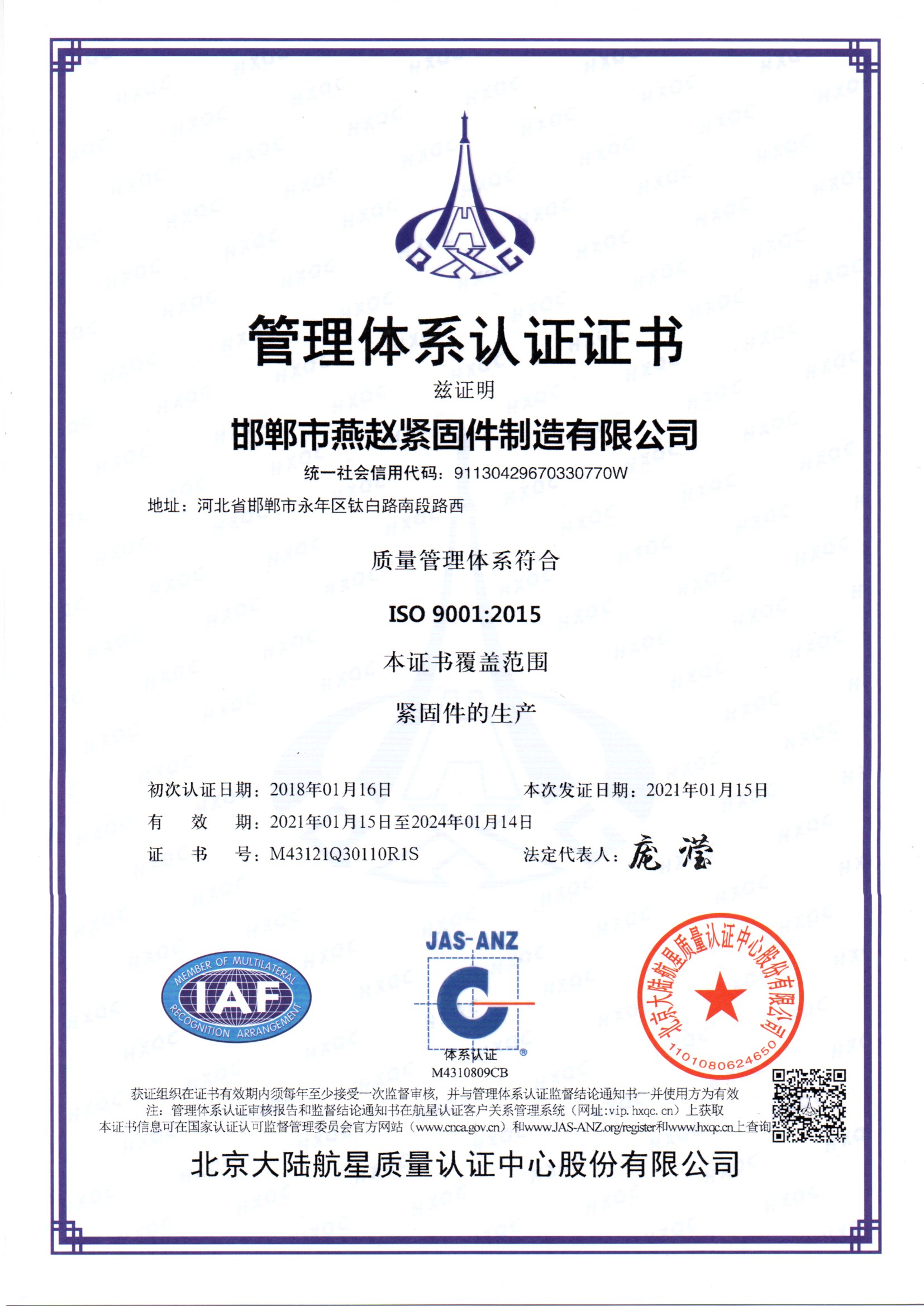

2. Quality Assurance Ensure that the manufacturer adheres to quality control standards. Look for certifications such as ISO certification, which indicates a commitment to quality.

3. Material Options A good manufacturer should offer a range of material options to meet specific environmental and mechanical requirements.

4. Customer Service Opt for a supplier that prioritizes customer support. They should be able to provide technical assistance and guidance throughout the design and ordering process.

Conclusion

Custom SAE bolts play a vital role in the integrity and success of various applications across industries. By understanding the significance of these specialized fasteners, manufacturers can make informed decisions that enhance the performance and reliability of their products. Whether in automotive engineering, aerospace applications, or construction, custom SAE bolts are essential for meeting the unique challenges of modern engineering. Choosing the right manufacturer ensures that these crucial components are tailored to perfection, supporting the ongoing innovation and efficiency of industrial operations.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025