Custom ASTM Standard Hex Bolts for Reliable Industrial Applications

Dec . 11, 2024 03:51 Back to list

Custom ASTM Standard Hex Bolts for Reliable Industrial Applications

The Importance of Custom ASTM Hex Bolts in Modern Engineering

In the realm of engineering and construction, fasteners play a crucial role in ensuring structural integrity and longevity. Among the various types of fasteners, hex bolts stand out due to their versatility and strength. Custom ASTM hex bolts, in particular, are increasingly becoming a staple across various industries, thanks to their alignment with stringent standards set forth by the American Society for Testing and Materials (ASTM).

Understanding ASTM Standards

ASTM International, formerly known as the American Society for Testing and Materials, is an organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. The ASTM standards that pertain to hex bolts ensure that they meet specific performance specifications, which are vital for safety and durability. Custom ASTM hex bolts are designed not only to meet these criteria but also to be tailored to the specific needs of a project, providing a perfect balance between quality and customization.

Customization and Design Flexibility

One of the primary reasons for opting for custom ASTM hex bolts is the ability to modify them according to specific project requirements. Engineers often encounter unique challenges that standardized bolts cannot adequately address. By customizing hex bolts, they can ensure that the fasteners have the right dimensions, coatings, and material properties. For instance, a construction project in a coastal area might require bolts with enhanced corrosion resistance. Customization allows for the selection of materials that are specifically engineered to withstand harsh environmental conditions, thus extending the lifespan of the structure.

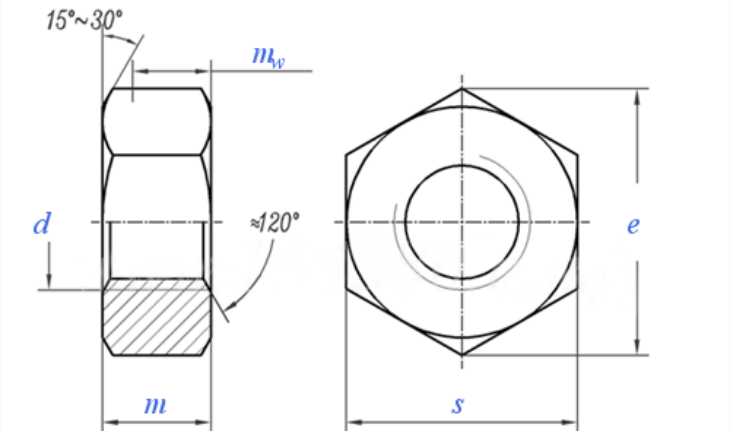

custom astm hex bolt

Material Selection and Performance

Material selection is paramount in the manufacturing of hex bolts. Custom ASTM hex bolts can be produced from an array of materials, including stainless steel, carbon steel, or specialty alloys. Each material presents its own set of mechanical properties. For example, stainless steel hex bolts are ideal for applications that require both strength and resistance to corrosion, making them suitable for outdoor structures or in chemical-processing environments. Conversely, carbon steel bolts can provide high tensile strength at a lower cost, making them a popular choice for large-scale industrial applications.

Quality Assurance and Testing

When it comes to fasteners, quality cannot be compromised. Custom ASTM hex bolts are subjected to rigorous testing to ensure they meet the necessary standards. This includes tensile testing, yield strength assessments, and fatigue tests, among others. This commitment to quality ensures that the bolts not only perform as intended but also contribute to the overall safety and reliability of the structures they are used in. Utilizing custom ASTM hex bolts also facilitates traceability, as manufacturers are often required to provide certificates of compliance, detailing the origin of the materials and the testing results.

Conclusion

In summary, custom ASTM hex bolts represent a vital component in the construction and manufacturing industries. Their ability to be tailored to specific applications combined with the assurance of quality and performance through ASTM standards makes them an invaluable asset. As engineering challenges continue to evolve, the demand for custom solutions will only increase, reinforcing the significance of custom ASTM hex bolts in achieving innovative and durable designs. As professionals seek to push the boundaries of what is possible in construction, these fasteners will undoubtedly remain at the forefront of their arsenal.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025