custom 5 8 bolts

Nov . 05, 2024 20:29 Back to list

custom 5 8 bolts

Understanding Custom 5/8 Bolts A Crucial Component in Engineering and Construction

In the realm of engineering and construction, the importance of fasteners cannot be overstated. Among these, bolts play a pivotal role in providing structural integrity and reliability to various assemblies. Custom 5/8 bolts are particularly noteworthy due to their versatility, strength, and adaptability in meeting specific project requirements. This article delves into the significance of custom 5/8 bolts and their applications across different industries.

What Are Custom 5/8 Bolts?

Custom 5/8 bolts refer to fasteners that are designed and manufactured to specific dimensions and materials tailored for particular applications. The term 5/8 denotes the diameter of the bolt, which is approximately 15.88 mm. These bolts are often produced to order, ensuring that they meet the precise requirements of a project or engineering specification.

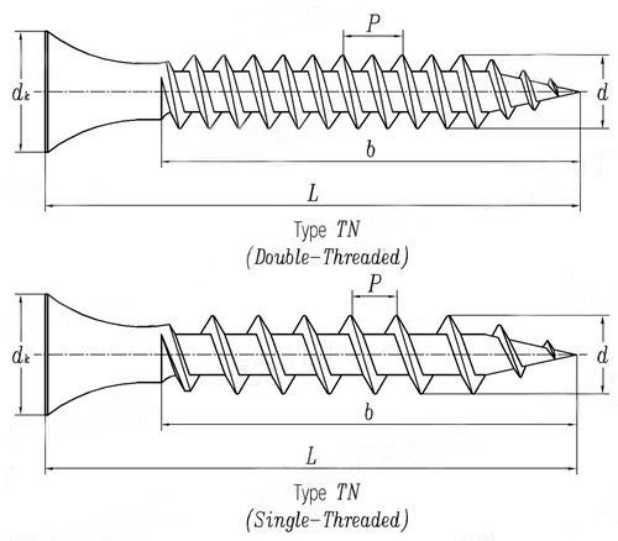

Manufacturers can customize various aspects of these bolts, including length, material grade, threading type, and surface finish. This level of customization allows engineers and designers to incorporate bolts that perform optimally under specific stress conditions, environmental factors, and workload requirements.

Materials and Manufacturing Processes

The choice of material for custom 5/8 bolts is critical, as it affects the bolt's performance and durability. Common materials include carbon steel, stainless steel, alloy steel, and even titanium for high-performance requirements. Each material offers distinct advantages; for instance, stainless steel is highly resistant to corrosion, making it suitable for outdoor or marine applications. In contrast, carbon steel is often preferred for its high tensile strength and cost-effectiveness.

The manufacturing process for custom bolts typically involves forging, machining, and sometimes heat treatment to enhance mechanical properties. Advanced technologies such as CNC machining and 3D printing are increasingly utilized to produce complex shapes and precise dimensions, enabling manufacturers to meet the exact specifications required by their clients.

Applications of Custom 5/8 Bolts

custom 5 8 bolts

Custom 5/8 bolts serve diverse applications across multiple industries. One of the primary sectors utilizing these fasteners is construction, where they are employed to secure structural components such as beams, columns, and frames. Their ability to withstand high loads makes them indispensable in high-rise buildings and bridges.

In the automotive industry, custom bolts are used in assembling various parts, ensuring that components remain secure and functional under vibration and stress. The aerospace sector also benefits from custom 5/8 bolts, where weight, strength, and reliability are critical.

Other applications include machinery manufacturing, marine hardware, and energy production sectors, particularly within wind turbines and solar panel installations. The ability to customize these bolts allows for enhancements that ensure safety and efficiency in applications where failure could lead to significant consequences.

Benefits of Using Custom Bolts

Opting for custom 5/8 bolts offers several advantages. First and foremost, they ensure a perfect fit for the specific application, which can enhance the overall performance and longevity of the assembly. Additionally, custom bolts can be designed to meet regulatory requirements and industry standards, reducing the risks associated with non-compliance.

Furthermore, custom bolts often lead to reduced assembly time, as they can be designed for easy installation or integration with other components, minimizing the need for additional fittings. Lastly, having the ability to source bolts that meet exact specifications can mitigate supply chain risks and ensure that projects can proceed without delays caused by mismatched parts.

Conclusion

Custom 5/8 bolts are a fundamental component in various engineering and construction applications. Their adaptability and strength make them an ideal choice for projects requiring secure and durable fastening solutions. By understanding the importance of these customized fasteners, engineers and designers can make informed decisions that contribute to the success and reliability of their projects. As industries continue to demand higher performance and stronger materials, the role of custom bolts will undoubtedly expand, showcasing the critical nature of these small but mighty components in modern construction and manufacturing.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025