Custom Flexplate Bolts for Enhanced Performance and Durability in High-Performance Engine Builds

Aug . 15, 2024 17:13 Back to list

Custom Flexplate Bolts for Enhanced Performance and Durability in High-Performance Engine Builds

Custom Flexplate Bolts Enhancing Performance and Durability

When it comes to high-performance automotive applications, ensuring that every component functions at its best is crucial. One often-overlooked yet essential part of an engine's assembly is the flexplate. Flexplates are vital for vehicles that use automatic transmissions, serving as a link between the engine and the transmission. Beneath all that power and torque, custom flexplate bolts play a significant role in maintaining the integrity and performance of this connection.

Understanding Flexplates and Their Importance

Flexplates are designed to absorb and compensate for vibrations and misalignments between the engine and transmission. Unlike standard flywheels used in manual transmissions, flexplates are lighter and have a unique design tailored to automatic vehicles. Their inherent flexibility allows for necessary movement while transferring power efficiently.

However, the strength and reliability of the flexplate largely depend on the quality of the bolts that secure it. Custom flexplate bolts are designed specifically to withstand the extreme conditions present in high-performance applications. They are typically crafted from high-strength materials to endure the torque loads generated by powerful engines.

Benefits of Custom Flexplate Bolts

1. Enhanced Durability Standard bolts may not provide the strength required in high-performance environments, leading to breakage or failure. Custom flexplate bolts are engineered to be more resilient, ensuring that they remain intact during intense operations.

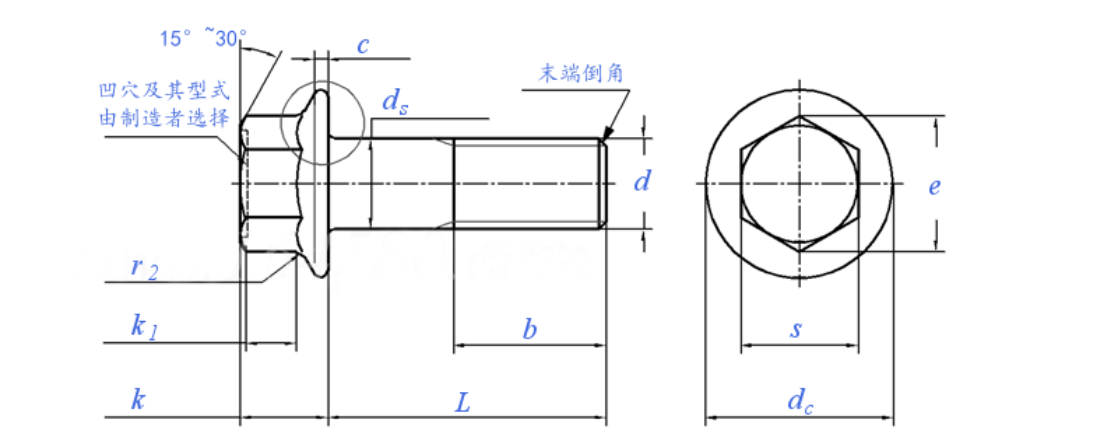

2. Precision Engineering Custom bolts can be made to exact specifications, ensuring a perfect fit for the flexplate and the crankshaft. This precision minimizes the risk of misalignment and vibrations, leading to smoother operation and increased longevity.

3. Weight Reduction Performance vehicles often focus on reducing weight to improve speed and handling. Custom bolts can be manufactured to eliminate unnecessary material without sacrificing strength, contributing to overall vehicle performance.

custom flexplate bolts

4. Corrosion Resistance Many manufacturers offer custom flexplate bolts with coatings or treatments that enhance corrosion resistance. In performance situations, where exposure to heat, oil, and other elements is common, this feature helps prevent degradation over time.

5. Improved Torque Capability Custom bolts can be designed to handle higher torque specifications, which is particularly beneficial for modified engines that operate beyond factory settings. This ensures that the flexplate remains securely attached, regardless of engine power changes.

Choosing the Right Custom Flexplate Bolts

When selecting custom flexplate bolts, it is essential to consider several factors

- Material Quality Look for bolts made from high-strength steel or alloys that can withstand the stresses of high-performance vehicles. - Thread Specifications Ensure that the thread size and pitch match the requirements of your specific engine and flexplate.

- Coatings and Treatments Select bolts with anti-corrosive coatings to prolong their lifespan and maintain performance under harsh conditions.

- Manufacturer Reputation Choose bolts from reputable manufacturers known for producing high-quality automotive components, as this can significantly impact performance and durability.

Conclusion

Custom flexplate bolts may seem like small components in the grand scheme of automotive engineering, but their contributions are significant. They play an essential role in ensuring that the engine and transmission work harmoniously, especially in high-performance setups. By opting for custom bolts that cater to specific needs, automotive enthusiasts can enhance the reliability, performance, and longevity of their vehicles. Whether building a racing machine or upgrading a daily driver, investing in quality flexplate bolts is a decision that pays off in performance and peace of mind.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025