carbon steel hexagon socket bolts factories

Sep . 19, 2024 15:16 Back to list

carbon steel hexagon socket bolts factories

The Evolution and Significance of Carbon Steel Hexagon Socket Bolts in Modern Manufacturing

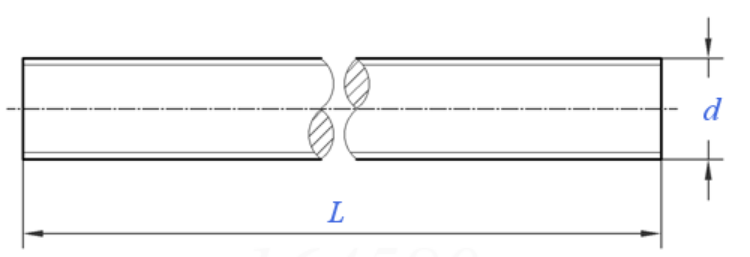

Carbon steel hexagon socket bolts play a vital role in various manufacturing processes, owing to their durability, strength, and versatility. These fasteners are specially designed with a hexagonal socket at their top, which allows for easy installation and removal using a compatible hex key or screwdriver. This article delves into the characteristics of carbon steel hexagon socket bolts, the processes involved in their manufacturing, and their applications across different industries.

Understanding Carbon Steel

Carbon steel is an alloy of iron and carbon, with varying levels of carbon content influencing its mechanical properties. The higher the carbon content, the stronger the steel becomes, but this also makes it less ductile. Carbon steel is popular in the production of hexagon socket bolts due to its excellent tensile strength, weldability, and affordability. It is categorized into different types, including low, medium, and high carbon steel, each suited for specific applications based on the required strength and flexibility.

Manufacturing Process

The production of carbon steel hexagon socket bolts involves several key steps. The process typically starts with the selection of high-quality carbon steel, which is then subjected to forging or machining. Forging involves shaping the heated steel under immense pressure to form the desired bolt shape, while machining involves cutting the steel into the correct dimensions using precision tools.

carbon steel hexagon socket bolts factories

Once the basic shape is formed, the bolts undergo a series of treatments, including heat treatment to enhance their hardness and strength. Afterward, the hexagonal socket is precisely machined into the bolt head, ensuring a perfect fit for hex keys. Finally, surface treatments may be applied, such as galvanization or powder coating, to improve corrosion resistance, particularly for bolts used in outdoor or harsh environments.

Applications in Various Industries

Carbon steel hexagon socket bolts find extensive applications across various industries. In construction, they are used to secure structural components, ensuring the stability and safety of buildings and bridges. In the automotive industry, these bolts are crucial for assembling vehicles, providing the necessary strength to withstand vibrations and mechanical stress.

Manufacturing machinery also relies heavily on hexagon socket bolts for secure assembly. Their ability to be tightened with a hex key makes them ideal for precision engineering where space restrictions may prevent the use of traditional wrenches. Additionally, electronics and appliance sectors utilize these bolts to secure components, ensuring reliability and performance.

Conclusion

The significance of carbon steel hexagon socket bolts in modern manufacturing cannot be overstated. Their strength, adaptability, and ease of use make them essential in a variety of applications, from construction to automotive engineering and beyond. As industries continue to evolve, the demand for high-quality fasteners is likely to increase, prompting factories to innovate and refine their production processes. With advancements in materials science and manufacturing techniques, the future of carbon steel hexagon socket bolts seems promising, reaffirming their status as a cornerstone in the realm of engineering and manufacturing. Whether you're a manufacturer or an end-user, understanding these fasteners' importance can lead to better design choices and enhanced product performance.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025