bolts for trailer hitch supplier

Dec . 02, 2024 06:27 Back to list

bolts for trailer hitch supplier

The Importance of Quality Bolts for Trailer Hitch Suppliers

When it comes to towing and transporting heavy loads, the role of trailer hitches is paramount. However, the effectiveness and safety of a trailer hitch largely depend on the quality of its components, particularly the bolts. For trailer hitch suppliers, ensuring that the bolts they provide are of the highest quality should be a top priority. This article will discuss the importance of quality bolts for trailer hitches and what suppliers should consider when sourcing these essential components.

Understanding the Role of Bolts in Trailer Hitches

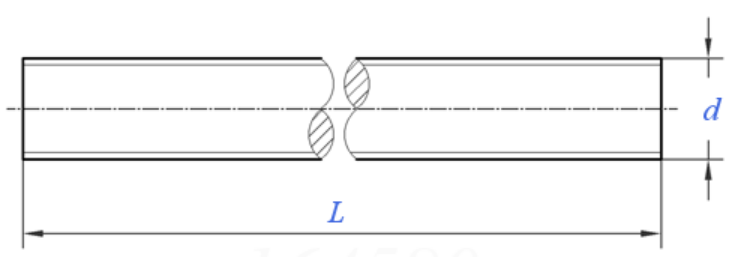

Bolts serve as essential fasteners that hold various components of a trailer hitch together. They connect the hitch to the vehicle, ensuring that it remains secure during transit. If a bolt fails, it can lead to catastrophic results, including accidents and damages to both the towing vehicle and the trailer. Therefore, the integrity of these bolts is crucial for safety.

Moreover, the load-bearing capacity of a trailer hitch largely depends on the strength and durability of the bolts used. They must withstand significant forces and stresses, especially when hauling heavy loads. Manufacturers often specify the sizes and types of bolts needed for their trailer hitches, and suppliers must adhere to these specifications to ensure compatibility and safety.

Material Quality and Specifications

The materials used to manufacture trailer hitch bolts are a determining factor in their performance. Most high-quality bolts are made from steel, often treated to resist corrosion and wear. Common treatments include galvanization and black oxide coatings that improve durability and longevity. Suppliers should ensure that the bolts they offer meet industry standards and specifications, such as ASTM (American Society for Testing and Materials) standards.

It’s also essential for suppliers to provide various grades of bolts, as different applications may require different strengths. For example, Grade 5 and Grade 8 bolts are commonly used in trailer hitches due to their superior tensile strength. Suppliers need to educate their customers on the differences among these grades to help them make informed choices.

Importance of Testing and Certification

bolts for trailer hitch supplier

To guarantee the safety and reliability of the bolts, rigorous testing and certification processes are essential. Trailer hitch suppliers should source their bolts from manufacturers that conduct thorough quality control measures. This includes tensile testing, fatigue testing, and torque testing to ensure that each bolt can withstand the rigors of towing.

In addition, suppliers should look for bolts that come with certification marks, indicating compliance with relevant safety standards. Certifications, such as ISO 9001 for quality management systems, can serve as a testament to the reliability and quality of the bolts being sold.

Inventory and Variety

A well-rounded inventory is vital for any trailer hitch supplier. Customers will have different needs depending on their specific towing applications, and having a variety of bolts in various sizes and specifications can help meet those demands. Furthermore, suppliers should consider offering additional accessories, such as lock washers and nuts, to provide a complete solution for customers.

Maintaining stock of high-demand items and keeping abreast of market trends can also enhance a supplier's reputation. For instance, as more consumers lean towards building custom trailers for specific uses, having specialized bolts available can ensure suppliers remain competitive in a rapidly changing market.

Customer Education and Support

Lastly, educating customers about the importance of using the right bolts for their specific trailer hitch applications cannot be overstated. Suppliers should provide customers with detailed product descriptions and usage guidelines to help them make the best choice. Moreover, offering technical support and consultation services can enhance customer satisfaction and loyalty.

In conclusion, trailer hitch suppliers play a critical role in ensuring the safety and reliability of towing vehicles by providing high-quality bolts. From material choice and testing to inventory management and customer education, suppliers must prioritize every aspect of bolt supply. By doing so, they contribute not only to the efficiency of towing operations but also to the safety of countless drivers on the road. Quality bolts are not just components; they are the backbone of safe and reliable trailer towing systems.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025