black oxidation hex bolts company

Nov . 18, 2024 20:31 Back to list

black oxidation hex bolts company

The Significance of Black Oxidation in Hex Bolts A Comprehensive Overview

In the dynamic world of manufacturing and engineering, the choice of fasteners plays a pivotal role in the integrity and longevity of mechanical structures. Among various fasteners, hex bolts are particularly prominent due to their robust design and versatility. In recent years, the process of black oxidation has garnered attention as an essential treatment for hex bolts, enhancing both performance and protection against environmental elements.

Understanding Black Oxidation

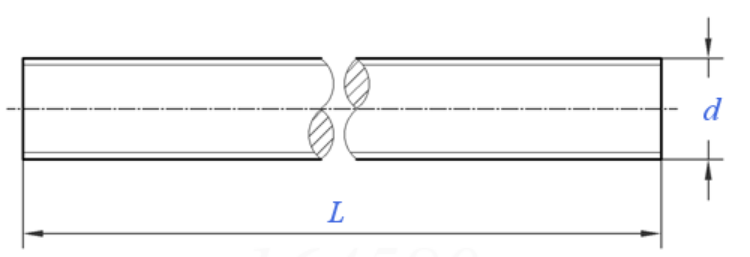

Black oxidation, also known as black oxide, is a conversion coating process that involves the creation of a thin layer of magnetite (Fe3O4) on the surface of steel or iron components. This process not only alters the surface color to a deep black finish but also provides several functional benefits. Unlike other coatings, black oxide does not add dimension to the part, making it an ideal finish for precision components such as hex bolts.

The black oxidation process is typically carried out in a series of steps, including cleaning, oxidizing, and sealing. The cleaning step involves degreasing the bolts to ensure that all contaminants are removed from the surface. After cleaning, the bolts are submerged in a hot alkaline oxidation solution. This step ensures that a uniform black layer is formed over the entire surface. Finally, the bolts are treated with a sealing oil that enhances corrosion resistance and helps to prevent oxidation.

Advantages of Black Oxidation for Hex Bolts

The application of black oxidation to hex bolts offers a range of advantages, making them an excellent choice for various applications

1. Corrosion Resistance The black oxide layer significantly enhances the corrosion resistance of hex bolts. This is particularly important in environments where these fasteners are exposed to moisture, chemicals, or other corrosive elements. While not entirely rust-proof, black oxidation provides a protective barrier that slows down the oxidation process.

black oxidation hex bolts company

2. Improved Aesthetics The deep black finish of black oxidized bolts provides an attractive appearance that can enhance the overall look of mechanical assemblies. This is especially valuable in applications where visual appeal is a consideration.

3. Reduced Friction The smooth surface of black oxidized hex bolts reduces friction during installation and operation. This characteristic is beneficial in applications where fasteners are frequently tightened or loosened, as it can lead to lower wear and longer lifespan for both the bolt and the connected components.

4. Enhanced Lubrication The sealing oil used in black oxidation can retain lubricants, making it easier to apply further lubrication as needed. This property is particularly advantageous in high-stress applications, where lubrication is essential to prevent galling and seizing.

5. Cost-Effective Solution Compared to more expensive coatings like zinc plating or galvanizing, black oxidation is a cost-effective solution for manufacturers. It allows for lower production costs without compromising quality or performance.

Applications of Black Oxidized Hex Bolts

Black oxidized hex bolts are widely used across various industries, including automotive, aerospace, construction, and machinery manufacturing. Their exceptional properties make them suitable for high-stress applications, such as engine components, suspension systems, and heavy machinery. Moreover, the black oxidized finish prevents the unwanted reflection of light, making these bolts an ideal choice for applications in stealth technology, military equipment, and outdoor recreational gear.

Conclusion

In summary, the black oxidation process offers significant benefits for hex bolts, enhancing their performance, durability, and aesthetic appeal. As industries continue to prioritize reliability and efficiency, the demand for black oxidized hex bolts is likely to grow. By investing in high-quality black oxidized fasteners, manufacturers can ensure the longevity and stability of their products, ultimately leading to greater customer satisfaction and safety in production.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025