allen bolts manufacturers

Nov . 02, 2024 20:56 Back to list

allen bolts manufacturers

The Evolution and Importance of Allen Bolts in Manufacturing

In the vast realm of industrial manufacturing, fasteners play an essential role in ensuring the integrity and reliability of various applications. Among these, Allen bolts—also known as hex socket bolts—have gained immense popularity due to their unique design and operational advantages. Understanding the significance of Allen bolts and their manufacturing process can provide insight into their critical role in various industries.

Understanding Allen Bolts

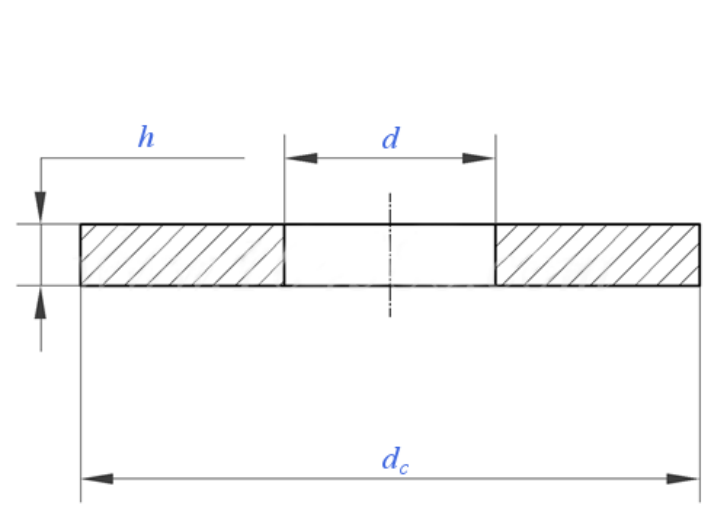

Allen bolts are characterized by their hexagonal socket drive, which requires an Allen wrench (or hex key) for installation and removal. This design allows for a flush finish—where the bolt head doesn't protrude above the surface—making them suitable for applications where space is at a premium. They are often used in furniture, automotive, and machinery construction, among other fields. Their ability to provide a secure and easily adjustable fastening solution has made them a preferred choice for engineers and manufacturers alike.

Manufacturing Process

The production of Allen bolts involves several key stages. Initially, high-quality raw materials, such as carbon steel or stainless steel, are sourced to ensure durability and corrosion resistance. The manufacturing process begins with machining, where the steel is cut and shaped into the desired form. This is followed by the critical phase of creating the hex socket drive. Advanced CNC (Computer Numerical Control) machines are often employed for precision cutting, ensuring that the socket dimensions comply with industry standards.

allen bolts manufacturers

Heat treatment is then applied to enhance the tensile strength of the bolts, providing the ability to withstand significant shear forces. Finally, the bolts undergo surface finishing processes, such as zinc plating or black oxide coating, which not only improves their aesthetic appeal but also adds an extra layer of protection against environmental factors.

The Role of Allen Bolt Manufacturers

Allen bolt manufacturers are crucial players in the supply chain, providing high-quality fasteners that meet rigorous standards. To fulfill the diverse needs of various industries, these manufacturers often offer custom solutions, tailoring bolt dimensions and materials to specific applications. Additionally, adherence to quality certifications, such as ISO 9001, assures clients of their commitment to excellence.

Moreover, the competitiveness in this sector drives innovation. Manufacturers continually explore new materials and production techniques to enhance performance and reduce costs. This evolution not only improves the product but also contributes to sustainability efforts by optimizing resource use and minimizing waste.

Conclusion

Allen bolts represent a remarkable intersection of design ingenuity and manufacturing prowess. Their unique features make them indispensable in a multitude of applications, driving the growth of various industries. As technology progresses, the role of Allen bolt manufacturers will continue to evolve, emphasizing the importance of quality, customization, and sustainability. The future of manufacturing is undoubtedly intertwined with the continued development of such essential components, ensuring that the industry remains efficient, reliable, and poised for growth.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025