a325 tc bolts factories

Dec . 10, 2024 11:52 Back to list

a325 tc bolts factories

The Landscape of A325 TC Bolts Manufacturing

When it comes to structural steel connections, A325 TC (Tension Control) bolts are essential components in ensuring the integrity and safety of various constructions, including bridges, high-rise buildings, and industrial facilities. The manufacturing of A325 TC bolts is a specialized field, demanding precision engineering and quality control to meet stringent industry standards.

Understanding A325 TC Bolts

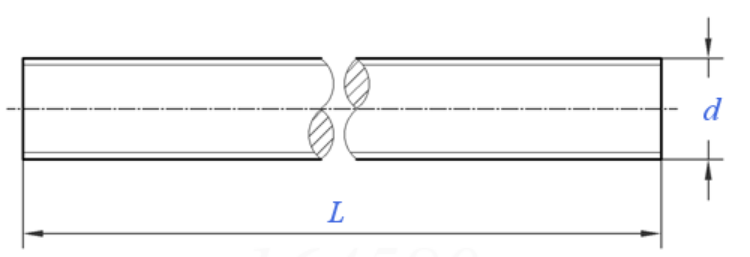

A325 TC bolts are heavy-duty fasteners designed to provide strong tensile strength and reliable performance under load. They are made from carbon steel, and typical applications require their resistance to shearing forces and capability to withstand considerable tension. The term TC refers to the tension control feature that allows for consistent installation torque, which is vital in avoiding over-torquing and under-torquing scenarios during fastening.

The key to A325 TC bolts’ effectiveness lies in their installation process, often executed using a tension-control method. This procedure involves a special design where the bolt is coupled with a matching nut and sometimes washers, and the assembly uses a wrench that twists the bolt until it reaches a specified tension level, at which point a break-off thread or point signals complete torque. This mechanical process ensures that the bolts are installed uniformly, reducing the risk of fastener failure.

The Manufacturing Process

The production of A325 TC bolts involves several stages, each contributing to the overall quality and performance of the final product. The primary steps encompass raw material selection, forging, heat treatment, threading, and inspection.

1. Raw Material Selection The manufacturing process begins with the selection of high-quality carbon steel, which is chosen for its mechanical properties that contribute to the bolt’s performance.

2. Forging The selected steel is heated to a high temperature and then forged into the desired shape. This process enhances the strength of the bolt through grain refinement.

3. Heat Treatment After forging, the bolts undergo heat treatment, which alters the microstructure of the steel, increasing toughness and tensile strength, thereby providing the performance characteristics needed for structural applications.

a325 tc bolts factories

4. Threading This step involves precision machining to create the necessary threads on the bolts. The threading must meet specific standards to ensure compatibility with nuts and washers.

5. Inspection and Testing Following production, A325 TC bolts are subjected to rigorous testing and inspection processes. These may include tensile tests, hardness tests, and visual inspections to ensure no defects and adherence to standards such as ASTM specifications.

Choosing a Reliable A325 TC Bolt Manufacturer

Selecting a reliable manufacturer for A325 TC bolts is crucial for any construction project. Several factors should be considered when evaluating a manufacturer

- Certification and Compliance The manufacturer should comply with industry standards, such as ASTM and ISO certifications, confirming their processes and products meet quality and reliability expectations.

- Experience and Reputation Manufacturers with a long-standing reputation in the market tend to have proven processes and quality assurance measures that instill confidence in their products.

- Customization Capabilities Certain projects may require custom specifications; therefore, a manufacturer’s ability to tailor their products to meet unique needs is another aspect to consider.

- Post-Sales Support Excellent customer service and support, including rapid response times and assistance with technical inquiries, can be indicators of a reputable supplier.

Conclusion

A325 TC bolts play a critical role in ensuring the structural integrity of various construction projects. The complexities of their manufacturing process highlight the importance of precision, quality control, and adherence to industry standards. As the construction industry continues to evolve, selecting quality A325 TC bolts from reputable manufacturers will remain a fundamental aspect of ensuring safety and durability in infrastructure development. As demand rises for robust construction materials, the landscape of A325 TC bolt factories will likely grow in innovation and capability, supporting the future of construction.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025