Top Manufacturers of 5% Lag Bolts in 2016 for Quality Construction Needs

Nov . 29, 2024 14:29 Back to list

Top Manufacturers of 5% Lag Bolts in 2016 for Quality Construction Needs

The Landscape of 5% Lag Bolts Manufacturing in 2016

In 2016, the bolt manufacturing industry witnessed significant changes and innovations, particularly in the production of lag bolts. These fasteners are essential in construction and woodworking, specifically designed to attach heavy objects to wood or for securing lumber in various structural applications. A surge in demand for robust and reliable fastening solutions has emphasized the need for high-quality manufacturing processes, including advancements in materials and production technology.

Understanding Lag Bolts

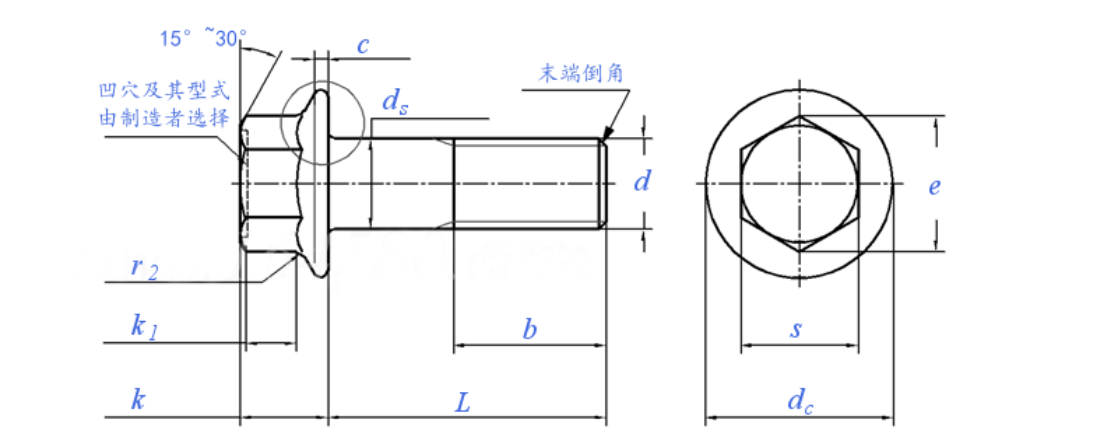

Lag bolts, also known as lag screws, are heavy-duty fasteners that are typically used when a more robust solution is required than standard screws can provide. Their unique design features a large diameter, a coarse thread, and a hexagonal head, making them efficient in creating secure connections. They are predominantly made from high-strength materials, with varying levels of corrosion resistance depending on their intended use. The 5% category, referring to the industry standards and specifications, indicates a focus on specific applications that require high reliability under stress.

Trends in Manufacturing

In 2016, several notable trends emerged within lag bolt manufacturing. First, there was an increased shift towards automation and advanced manufacturing techniques. Companies invested in CNC (Computer Numerical Control) technology, which allowed for precision engineering and significant production efficiency. By utilizing automated assembly lines, manufacturers could produce lag bolts in higher volumes and with greater consistency in quality.

Second, the rise in eco-consciousness among consumers influenced manufacturers to explore sustainable practices. Many companies began sourcing recycled materials and implementing eco-friendly production processes, positioning themselves favorably within an increasingly competitive market. The emphasis on sustainability not only appealed to environmentally aware customers but also met regulatory requirements that were becoming stricter around the globe.

Quality and Standards

5 16 lag bolts manufacturers

Quality assurance was another critical factor in the 2016 lag bolt manufacturing landscape. Manufacturers adhered to rigorous standards set by the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). Achieving certification not only assured customers of the product reliability but also enhanced the reputation of manufacturers in a crowded market. Rigorous testing procedures became standard practice to evaluate the tensile strength, corrosion resistance, and overall durability of the bolts.

The Role of Technology

Technological advancements extended beyond mere automation; they also encompassed the integration of data analytics and IoT (Internet of Things) components in manufacturing processes. Many manufacturers adopted smart technologies that allowed for real-time monitoring of production metrics, which helped to quickly identify and mitigate any potential quality issues. Predictive maintenance, supported by data analytics, further enhanced machine uptime and operational efficiency.

Market Dynamics and Challenges

Despite the positive trends in manufacturing, the lag bolt industry faced challenges in 2016. The volatility of raw material prices, largely due to geopolitical factors, created uncertainty. Companies had to navigate a delicate balance between maintaining profitability and ensuring competitive pricing for their products. Additionally, the competition from international manufacturers introduced challenges related to cost, quality, and delivery times.

Conclusion

In conclusion, 2016 was a pivotal year for the lag bolt manufacturing industry, characterized by technological advancements, improved sustainability practices, and an unwavering commitment to quality. The landscape of lag bolt production was shaped by the industry's responsiveness to market demands and the necessity of adhering to stringent quality standards. As manufacturers continued to innovate and adapt, the lag bolt remained a reliable component in various construction and woodworking projects, proving its essential role in ensuring structural integrity and safety. Going forward, the interplay of technology, quality assurance, and market dynamics will dictate the continued evolution of lag bolt manufacturing in an increasingly demanding world.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025