3 8 Lag Screws Manufacturers and Production Processes Explained

Nov . 11, 2024 03:49 Back to list

3 8 Lag Screws Manufacturers and Production Processes Explained

The Importance of 3 8% Lag Screws in the Manufacturing Industry

In today’s manufacturing landscape, precision and reliability are paramount. Among the myriad of fasteners used in various construction and production processes, lag screws stand out as a vital component, particularly the 3 8% variant. These screws play an essential role in ensuring structural integrity and durability, making them a preferred choice in many applications.

Understanding Lag Screws

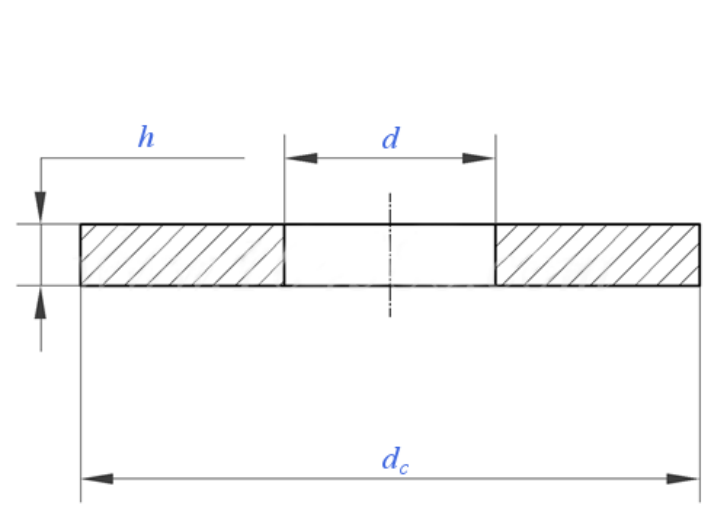

Lag screws, also known as lag bolts, are heavy-duty fasteners designed for wood-to-wood or wood-to-metal connections. Their distinctive features include a hexagonal head and a threaded shaft that extends deep into the material, providing a solid grip. Unlike regular screws, lag screws have a coarser thread, which allows them to penetrate and hold onto the material without the need for a pre-drilled hole in many applications.

The designation 3 8% denotes specific properties or standards that these screws must meet. The first number typically represents the diameter (in millimeters) of the screw, while the second indicates the percentage of tensile strength or other mechanical properties. These specifications ensure that the lag screws can withstand the stresses and strains of various applications.

Applications in Various Industries

Lag screws are extensively used across multiple sectors, including construction, manufacturing, and furniture production. In the construction industry, they are often utilized to secure wooden beams, trusses, and other structural components. Their ability to hold significant weight and resist shear forces makes them ideal for both residential and commercial builds.

In manufacturing, these screws are used to assemble machinery, fixtures, and equipment. Industries that require robust assemblies, such as automotive, aerospace, and heavy machinery, leverage the strength of 3 8% lag screws to ensure that their products can withstand operational demands.

Moreover, the furniture industry benefits significantly from these fasteners. When crafting sturdy and durable pieces, manufacturers choose lag screws to join various components securely. This choice not only enhances the overall integrity of the furniture but also improves longevity, which is a critical selling point in today's market.

3 8 lag screws factories

The Manufacturing Process of Lag Screws

The production of lag screws involves several intricate steps that ensure their quality and performance. Typically, the process begins with high-quality steel, which is chosen for its inherent strength and ability to resist corrosion when properly treated.

The steel is then cut and shaped into the desired dimensions, followed by the threading process. This stage is crucial, as the thread design impacts the screw’s grip and load-bearing capacity. Advanced machinery is used to create precise threads that align with the stringent standards set for the 3 8% lag screws.

After threading, the screws undergo a treatment process for durability and corrosion resistance, often involving coatings such as zinc plating or black oxide. This not only extends the lifespan of the screws but also enhances their performance in various environmental conditions.

Quality Control and Standards

Given their critical role in ensuring structural integrity, quality control in the manufacturing of lag screws is non-negotiable. Factories adhere to international standards and certifications, which govern the production, testing, and performance criteria for these fasteners. Rigorous testing procedures, including tensile tests and shear tests, ensure that the screws can handle the forces they will encounter in real-world applications.

Manufacturers often conduct random sampling during production runs to verify that each batch of lag screws meets the established quality standards. This commitment to quality not only builds trust with clients but also minimizes the risk of failures in the field.

Conclusion

In conclusion, 3 8% lag screws hold a significant place in the manufacturing and construction sectors due to their strength, reliability, and versatility. Their unique design and robust characteristics make them indispensable for a variety of applications, from structural components to intricate machinery assemblies. As industries continue to evolve, the demand for high-quality fasteners like lag screws will only increase, underscoring the importance of maintaining stringent manufacturing standards and practices. With ongoing advancements in materials and production techniques, the future of lag screws appears bright, promising enhanced performance and even greater applications across various industries.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025