Suppliers for 12-inch Bolts in Various Materials and Specifications

Nov . 01, 2024 19:56 Back to list

Suppliers for 12-inch Bolts in Various Materials and Specifications

Exploring 12 Inch Bolts Suppliers Quality and Considerations

When it comes to construction, manufacturing, or any other industry that relies on sturdy fastening solutions, the significance of high-quality bolts cannot be overstated. Among various sizes, 12-inch bolts stand out due to their unique applications and the specific requirements they cater to. As industries evolve, the demand for reliable 12-inch bolt suppliers has significantly increased. This article delves into several essential factors to consider when searching for these suppliers.

Understanding 12-Inch Bolts

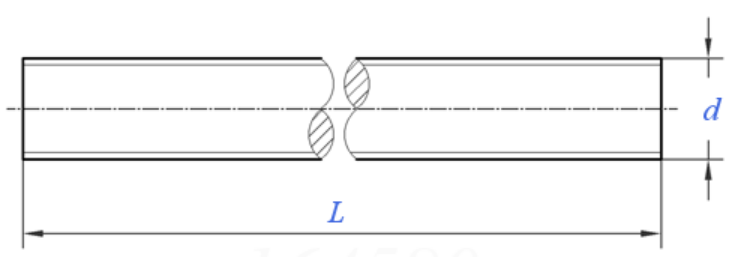

12-inch bolts are classified based on their diameter, material, thread type, and tensile strength. These fasteners are commonly used in heavy-duty applications, such as structural assemblies, bridge construction, and equipment manufacturing. They serve to provide secure and lasting connections in environments where durability is paramount. Therefore, sourcing these bolts from reputable suppliers is critical.

Key Considerations When Choosing Suppliers

1. Quality of Products The most crucial aspect is to ensure that the bolts meet industry standards. Suppliers should provide materials that comply with relevant regulations, such as ASTM or ISO standards. High-quality bolts will typically undergo rigorous testing for tensile strength, corrosion resistance, and load-bearing capacity.

2. Material Selection Bolts can be made from various materials, including carbon steel, stainless steel, and alloy steel. Each material has its advantages and drawbacks based on the specific application. As such, a supplier should offer options that align with your project requirements, ensuring that the chosen material will withstand environmental and mechanical stresses.

12 inch bolts suppliers

3. Customization Options In many cases, a one-size-fits-all approach does not apply. Customization in thread type, length, and finish (such as coatings for corrosion resistance) can be essential in meeting specific project deadlines or design specifications. Suppliers willing to provide custom solutions can be invaluable partners.

4. Delivery and Lead Times In construction and manufacturing, time is of the essence. Delays in receiving essential materials can halt projects and lead to increased costs. It is essential to choose suppliers known for their timely delivery and reliable logistics. Always inquire about their lead times on both standard and custom orders.

5. Pricing and Payment Terms While price shouldn’t be the sole determining factor, it’s crucial to ensure that the cost aligns with your budget. Suppliers should provide transparent pricing structures, along with flexible payment terms that accommodate your financial strategy.

6. Customer Support and Service The relationship with a supplier should go beyond transactional. Excellent customer service, knowledgeable staff, and after-sale support can make a significant difference. A responsive supplier will assist not just in the purchasing process but also in addressing any post-delivery issues that may arise.

7. Reputation and Reviews Finally, consider the supplier’s reputation in the industry. Reviews from previous customers can provide insights into their reliability, product quality, and service. A strong track record in providing 12-inch bolts is often a good indicator of a supplier's overall capability.

Conclusion

Finding the right 12-inch bolts supplier is fundamental for the success of any project that requires significant fastening solutions. By concentrating on quality, customization, timely delivery, pricing, and customer service, you can select a supplier that meets your specific needs. As industries continue to grow and evolve, partnering with a trustworthy supplier will ensure that your projects remain on track, ultimately leading to greater operational efficiency and success.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025