oem 9mm bolts

डिसेंबर . 23, 2024 21:55 Back to list

oem 9mm bolts

Understanding OEM 9mm Bolts A Comprehensive Guide

When discussing the components that play a vital role in assembly and manufacturing processes, one cannot overlook the importance of bolts. Among these, OEM 9mm bolts are particularly noteworthy. OEM, or Original Equipment Manufacturer, indicates that these bolts are produced to meet the specific standards set by manufacturers for their products. This article delves into the specifications, applications, benefits, and considerations surrounding OEM 9mm bolts.

What Are OEM 9mm Bolts?

OEM 9mm bolts are fasteners with a diameter of 9 millimeters, designed for a range of industrial and automotive applications. These bolts ensure that machine components are securely fastened together while maintaining structural integrity and performance. The OEM label signifies that these bolts are made to be exact replacements for parts used in original equipment, which ensures compatibility and reliability.

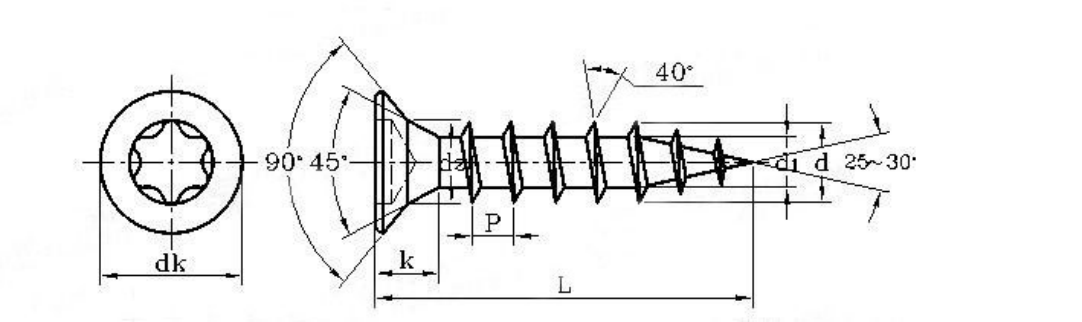

Specifications of 9mm Bolts

The specifications for OEM 9mm bolts include various factors such as material type, tensile strength, length, and head type. These bolts are typically made from high-strength materials, including alloy steel or stainless steel, designed to withstand specific loading conditions and environmental factors.

Key specifications may include

- Diameter 9mm - Length Varies depending on the application (standard lengths range from 20mm to over 100mm) - Grade Different grades correspond to different tensile strengths (e.g., Grade 8.8 or 10.9 in metric terms). - Coating Options such as zinc plating, black oxide, or galvanization to enhance corrosion resistance.

Selecting the correct specifications is crucial since they directly affect the performance and safety of the assembly.

Applications of OEM 9mm Bolts

oem 9mm bolts

OEM 9mm bolts can be found in various sectors including automotive manufacturing, machinery assembly, and even in structural applications. In the automotive industry, for example, these bolts are essential for securing engine components, bodywork, and other critical systems. In industrial machinery, they are used to fasten components such as bearings, gears, and frames, ensuring that parts remain securely connected under stress and vibration.

Benefits of Using OEM 9mm Bolts

1. Quality Assurance OEM parts are manufactured to meet stringent quality standards. This not only ensures reliability but also longevity, reducing the risk of failure under operational stress.

2. Perfect Fit As these bolts are specifically designed for particular applications, they fit perfectly, reducing the chances of issues such as stripping or shear failure.

3. Consistent Performance OEM 9mm bolts are designed to perform consistently, thereby enhancing the overall performance of the machinery or vehicle in which they are used.

4. Warranty Compatibility Using OEM parts often helps in maintaining the warranty of the machinery or vehicle, as manufacturers typically require OEM components for repairs and replacements.

Considerations When Choosing OEM 9mm Bolts

While OEM 9mm bolts offer many advantages, there are also considerations to keep in mind. The cost can be higher compared to generic or aftermarket equivalents. However, the investment often pays off in terms of performance and durability. It’s also essential to ensure the bolts meet the specific requirements of your assembly. Consulting technical documentation or a knowledgeable supplier can help make the right choice.

Conclusion

In summary, OEM 9mm bolts are crucial components in various industries, offering quality, reliability, and compatibility for numerous applications. Understanding their specifications and the benefits they provide can significantly influence the performance and durability of the equipment they are part of. By considering the right specifications and recognizing the importance of using OEM parts, manufacturers and mechanics alike can ensure that their assemblies remain safe and effective over time. Selecting the right bolt not only enhances the integrity of the assembly but also contributes to the overall success of the operational processes involved.

Latest news

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025