Understanding Grommets and Their Use with Screws in Various Applications

11-р сар . 08, 2024 02:17 Back to list

Understanding Grommets and Their Use with Screws in Various Applications

Understanding Grommets for Screws Enhancing Performance and Durability

In various applications ranging from electronics to construction, grommets play a crucial role in securing screws and preventing damage to materials. These small but significant components act as protective rings placed within holes where screws are inserted, ensuring that the integrity of the material is maintained while providing enhanced performance. This article will delve into the importance of grommets for screws, their types, benefits, and application fields.

What are Grommets?

Grommets are typically made from rubber, plastic, or metal and are designed to reinforce holes in various materials, such as fabric, metal, or plastic. They can be found in numerous applications, serving as insulators, guides, and protective barriers. When it comes to screws, grommets prevent the sharp edges of the screw from damaging the surrounding material while also providing a secure fit that can withstand various environmental factors.

Types of Grommets for Screws

Grommets come in a range of designs and materials, each suited for different applications. The most common types include

1. Rubber Grommets These are typically used in situations where vibration dampening is essential, such as in automotive and machinery applications. Rubber grommets are flexible and compressible, effectively absorbing vibrations and shocks.

2. Plastic Grommets Lightweight and corrosion-resistant, plastic grommets are often employed in electronics and low-stress applications. They provide a moisture seal and protect sensitive components from dust and debris.

3. Metal Grommets Durable and strong, metal grommets are ideal for heavy-duty applications that require high tensile strength. They are commonly found in industrial settings or where exposure to harsh environmental conditions is expected.

Benefits of Using Grommets with Screws

The incorporation of grommets in screw applications provides several advantages

- Protection Against Damage One of the primary functions of grommets is to minimize potential damage to the material surrounding the screw. By distributing the load evenly and preventing direct contact, grommets safeguard against chafing, tearing, and other forms of wear and tear.

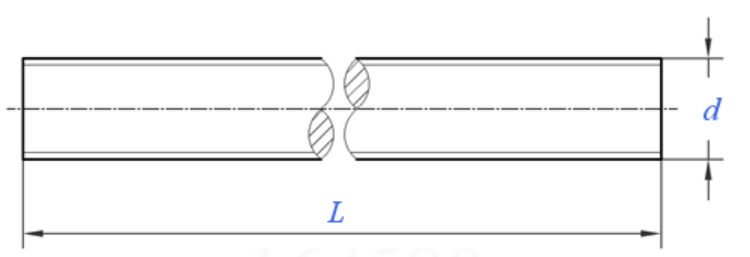

grommet for screws

- Vibration and Noise Reduction Grommets made from rubber or other flexible materials effectively absorb vibrations and reduce noise levels, which is particularly beneficial in automotive and machinery contexts where components are subjected to constant movement and stress.

- Moisture Protection In environments exposed to moisture, grommets can create a hermetic seal around screws, preventing water ingress that could lead to rust or corrosion. This feature is particularly crucial in outdoor applications or in inclement weather conditions.

- Aesthetic Appeal In applications where appearance matters, such as in consumer electronics or finished products, grommets provide a neat and tidy finish, concealing the screw heads and holes.

Applications of Grommets for Screws

Grommets find extensive use across various industries

- Electronics In electronics, grommets prevent wire chafing and protect sensitive components from mechanical stress, making them crucial in circuit boards and appliance assembly.

- Automotive In vehicles, grommets secure components while mitigating noise and vibration, playing a significant role in vehicle comfort and integrity.

- Textiles In fashion and upholstery, grommets are used not only to secure fabric but also to enhance design aesthetics, often incorporated into bags, jackets, and other apparel.

- Construction In construction, grommets protect screws in panels and pipes, ensuring durability and longevity against the elements.

Conclusion

Grommets for screws may be small in size, but their impact on performance and durability is substantial. By understanding the different types of grommets and their benefits, industries can make informed decisions that enhance the integrity of their applications. Whether in electronics, automotive manufacturing, or construction, grommets serve as essential components that ultimately contribute to the longevity and reliability of products. As technology advances and the demand for high-quality assembly increases, the importance of using grommets in screw applications will continue to grow, cementing their role in modern manufacturing processes.

Latest news

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025

-

Silver Screws Supplier: High-Quality Fasteners for Various Industries

NewsJul.30,2025