Innovative Solutions for Self-Piercing Screw Manufacturing and Distribution

ഡിസം . 04, 2024 18:37 Back to list

Innovative Solutions for Self-Piercing Screw Manufacturing and Distribution

Self-Piercing Screws A Look into the Future of Fastening Solutions

In an ever-evolving manufacturing landscape, the demand for efficient, reliable, and innovative fastening solutions has never been higher. Among the various fasteners available on the market, self-piercing screws (SPS) have gained noteworthy attention for their ability to streamline assembly processes in diverse applications. The rise of self-piercing screw companies has revolutionized various industries by providing advanced fastening solutions that simplify assembly while ensuring durability and strength.

Understanding Self-Piercing Screws

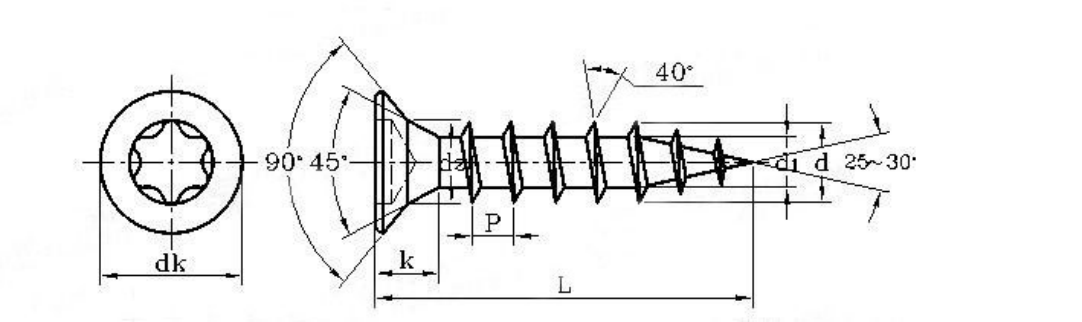

Self-piercing screws are specialized fasteners designed to penetrate materials without the need for pre-drilled holes. They are primarily used in the assembly of layered materials, such as sheet metal, plastics, and composites. The unique design of self-piercing screws features sharp threads and a tapered tip, which allows them to create a hole in the material while simultaneously anchoring themselves securely. This innovative design not only enhances productivity but also reduces the risk of errors and rework associated with traditional fastening methods.

Efficiency and Cost-Effectiveness

One of the most significant advantages of self-piercing screws is their ability to expedite the manufacturing process. By eliminating the need for pre-drilled holes, manufacturers can save valuable time during assembly. This efficiency translates into lower labor costs and increased output, making self-piercing screws a cost-effective option for many businesses. Companies can achieve faster production cycles, which is particularly crucial in industries like automotive, construction, and electronics, where time-to-market is critical.

Versatility in Applications

Self-piercing screws are not limited to a single industry; they find applications across various sectors. In the automotive industry, for instance, these screws are essential for assembling body panels and other components, ensuring a strong bond between layers while maintaining the integrity of the materials used. In construction, self-piercing screws are widely utilized in metal framing and roofing systems, providing reliable fastening in challenging environments. Furthermore, the electronics industry benefits from SPS in the assembly of casings and enclosures, where precision and strength are paramount.

self piercing screws company

Quality and Durability

The quality and durability of self-piercing screws are critical factors that construction and manufacturing companies prioritize. High-quality SPS from reputable manufacturers are engineered to withstand the rigors of different applications. They are often made from robust materials, such as stainless steel or carbon steel, and are treated with anti-corrosion coatings to ensure longevity. By investing in quality self-piercing screws, companies reduce the likelihood of failures or repairs, ultimately enhancing product reliability.

Environmental Considerations

As sustainability becomes a priority across industries, self-piercing screw companies are increasingly focusing on eco-friendly practices. This includes utilizing recyclable materials and adopting processes that minimize waste during production. Additionally, the efficiency of self-piercing screws can contribute to energy savings in manufacturing processes, as quicker assembly leads to reduced machinery run times. This alignment with environmental standards makes self-piercing screws an attractive option for businesses aiming to reduce their ecological footprint.

Innovations and Future Trends

The future of self-piercing screws holds promise as technological advancements continue to reshape the fastener industry. Companies are investing in research and development to create even more specialized screws and automation technologies that enhance the efficiency of fastening processes. Future innovations may include smart fasteners equipped with sensors that monitor structural integrity over time, contributing to predictive maintenance strategies in various applications.

Conclusion

As industries seek innovative solutions to enhance productivity, the role of self-piercing screw companies cannot be understated. These fasteners offer a blend of efficiency, versatility, and durability that meets the challenges of modern manufacturing. With a growing emphasis on quality and sustainability, self-piercing screws are poised to play a crucial role in shaping the future of fastening solutions across various sectors. In a world where time and resources are increasingly precious, self-piercing screws represent a smart choice for companies aiming to optimize their assembly processes and deliver unparalleled performance in their products.

Latest news

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025

-

Automatic Flush Bolts for Double Doors - Reliable Security, Easy Installation, Factory Direct Supply

NewsJul.05,2025

-

High-Quality 11mm Bolts Manufacturer Reliable 11mm Bolts Factory & Suppliers

NewsJul.05,2025