Scooter Fasteners Manufacturing Facilities and Their Impact on the Industry

Окт . 17, 2024 05:57 Back to list

Scooter Fasteners Manufacturing Facilities and Their Impact on the Industry

The Rising Demand for Scooter Bolts An Insight into Manufacturing Factories

In recent years, the popularity of scooters as a mode of transportation has surged across various cities around the globe. With the increasing reliance on eco-friendly and efficient travel options, the demand for quality parts, including scooter bolts, has become paramount. This article explores the landscape of scooter bolt manufacturing factories and their role in supporting the scooter industry.

Understanding Scooter Bolts

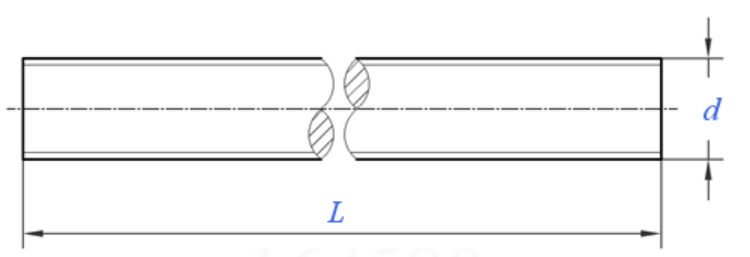

Scooter bolts are the small yet essential hardware components that play a critical role in assembling and securing various parts of a scooter. From the frame to the wheels, the quality and durability of scooter bolts are crucial for the overall safety and performance of the vehicle. Made from high-strength materials, these bolts undergo rigorous testing to ensure they can withstand the stresses of daily use and provide reliable performance under varying environmental conditions.

The Growing Market for Scooters

The global scooter market has expanded significantly, driven by factors such as urbanization, environmental consciousness, and the rising cost of traditional vehicles. As cities become more congested, scooters offer a convenient solution for short-distance travel. This shift towards two-wheeled transport has led to a corresponding increase in the production of scooters, and, consequently, the demand for scooter bolts and other components.

According to industry reports, the global scooter market is expected to continue its growth trajectory, with projections indicating a compound annual growth rate (CAGR) of over 7% in the coming years. As manufacturers ramp up production to meet this demand, the importance of a reliable supply chain for scooter components, including bolts, cannot be overstated.

Manufacturing Factories Backbone of the Industry

scooter bolts factories

Manufacturing factories specializing in scooter bolts are playing a crucial role in the supply chain. These factories are equipped with advanced machinery and technology that allow for precision engineering, ensuring each bolt meets the stringent quality standards required for use in scooters. Many factories employ skilled workers who are trained in the latest manufacturing processes, including automated production techniques that enhance efficiency.

Moreover, factories today are increasingly focusing on sustainable practices. With the environmental impact of production becoming a pressing concern, many manufacturers are adopting green technologies, such as using recycled materials and minimizing waste. This shift not only helps in reducing the carbon footprint of production but also aligns with the values of environmentally-conscious consumers.

Technological Advancements in Manufacturing

The landscape of scooter bolt manufacturing is not without its challenges. As the industry evolves, factories are investing in research and development (R&D) to innovate and improve the design and materials used in bolt production. Advances in metallurgy have led to the development of stronger and lighter bolts that enhance the overall quality of scooters.

Additionally, the implementation of Industry 4.0 technologies, such as IoT (Internet of Things) and AI (Artificial Intelligence), is revolutionizing manufacturing processes. Factories are now able to monitor production in real-time, predict maintenance needs, and streamline operations, which results in higher efficiency and lower costs. This technological integration ultimately leads to better products for scooter manufacturers and consumers alike.

Conclusion The Future of Scooter Bolts

As the scooter industry continues to flourish, the importance of high-quality scooter bolts remains undeniable. Manufacturing factories are at the heart of this growth, providing the essential components that ensure safety and performance in scooters. With ongoing advancements in manufacturing technologies and a commitment to sustainability, these factories are well-positioned to meet the challenges of the future.

The relationship between scooter manufacturers and bolt-producing factories is symbiotic, with both sectors relying on each other's capabilities to deliver successful products to the market. As urban transport continues to evolve, the focus on enhancing the quality and sustainability of scooter bolts will be essential in shaping the future of personal mobility solutions. Whether for leisure or commuting, scooters and their components, including bolts, will continue to play a vital role in the everyday lives of people around the world.

Latest news

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025