header bolts sbc

Фев . 19, 2025 02:50 Back to list

header bolts sbc

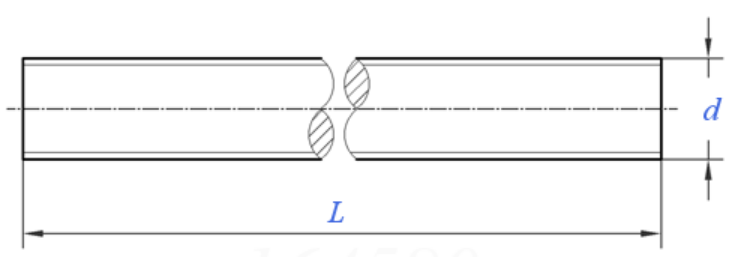

Elevating the performance of Small Block Chevy engines is often an intricate journey of understanding and choosing the right components. Among these, header bolts specifically designed for SBC (Small Block Chevy) can significantly influence engine efficiency and reliability — a crucial insight for both seasoned mechanics and automotive enthusiasts looking to optimize their engine setups.

Gaining an authoritative edge over DIY installations and ensuring trust from potential users involves providing clear guidance on compatibility and secondary features such as thread locker applications. Correct thread engagement not only assures robust installation but also contributes to the prevention of vibration-induced loosening, which is a common concern with high-performance engines. In elevated experience-driven scenarios, customer feedback on various header bolt products for SBC can shed light on their real-world performance beyond technical specifications. Reviews often emphasize superior performance in preventing exhaust gasket failures, resistance to loosening under high vibration, and maintenance of structural integrity under thermal stress. Such firsthand experiences are invaluable, offering practical perspectives on the reliability of different product options. Trust in a chosen product can be augmented through certifications and endorsements from recognized automotive bodies or performance workshops. When header bolts are recommended by industry experts or come with accolades, users are more assured of their purchase's quality and potential impact on engine performance. Lastly, a critical insider tip for maximizing SBC header performance involves regularly conducting inspections of the bolts post-installation, especially after initial thermal cycles. Re-torquing the bolts might be necessary as materials expand and contract when adjusted to operating temperatures. Regular maintenance schedules incorporating these checks can significantly enhance the lifespan and operational excellence of the headers and, by extension, the engine. In conclusion, the choice of SBC header bolts is pivotal in driving the overall efficiency and durability of Small Block Chevy engines. Incorporating insights on materials, torque specifications, design ease, and maintenance practices not only elevates engine performance but also builds a trustworthy and authoritative user experience. For any vehicle enthusiast or mechanic aiming for optimal exhaust setup, understanding and selecting the right header bolts is a fundamental step that amplifies both the power and reliability of their Small Block Chevy engine.

Gaining an authoritative edge over DIY installations and ensuring trust from potential users involves providing clear guidance on compatibility and secondary features such as thread locker applications. Correct thread engagement not only assures robust installation but also contributes to the prevention of vibration-induced loosening, which is a common concern with high-performance engines. In elevated experience-driven scenarios, customer feedback on various header bolt products for SBC can shed light on their real-world performance beyond technical specifications. Reviews often emphasize superior performance in preventing exhaust gasket failures, resistance to loosening under high vibration, and maintenance of structural integrity under thermal stress. Such firsthand experiences are invaluable, offering practical perspectives on the reliability of different product options. Trust in a chosen product can be augmented through certifications and endorsements from recognized automotive bodies or performance workshops. When header bolts are recommended by industry experts or come with accolades, users are more assured of their purchase's quality and potential impact on engine performance. Lastly, a critical insider tip for maximizing SBC header performance involves regularly conducting inspections of the bolts post-installation, especially after initial thermal cycles. Re-torquing the bolts might be necessary as materials expand and contract when adjusted to operating temperatures. Regular maintenance schedules incorporating these checks can significantly enhance the lifespan and operational excellence of the headers and, by extension, the engine. In conclusion, the choice of SBC header bolts is pivotal in driving the overall efficiency and durability of Small Block Chevy engines. Incorporating insights on materials, torque specifications, design ease, and maintenance practices not only elevates engine performance but also builds a trustworthy and authoritative user experience. For any vehicle enthusiast or mechanic aiming for optimal exhaust setup, understanding and selecting the right header bolts is a fundamental step that amplifies both the power and reliability of their Small Block Chevy engine.

Latest news

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025

-

Silver Screws Supplier: High-Quality Fasteners for Various Industries

NewsJul.30,2025

-

Top Spike Wheel Nuts Supplier - High Quality & Custom Options Available

NewsJul.29,2025