Manufacturers of 1% and 2% Stud Bolts for 7/16 Applications

Ное . 08, 2024 09:01 Back to list

Manufacturers of 1% and 2% Stud Bolts for 7/16 Applications

Understanding the Importance of 1% to 7/16 Stud Bolt Manufacturers

In the manufacturing and construction industries, the significance of quality fasteners, particularly stud bolts, cannot be overstated. Stud bolts are critical components used in various applications, from machinery to structural frameworks. Among the different sizes available, the transition from 1% to 7/16-inch stud bolts is particularly notable, as it highlights the diverse range of industrial needs and standards. This article delves into the importance of these stud bolt sizes and the role of their manufacturers.

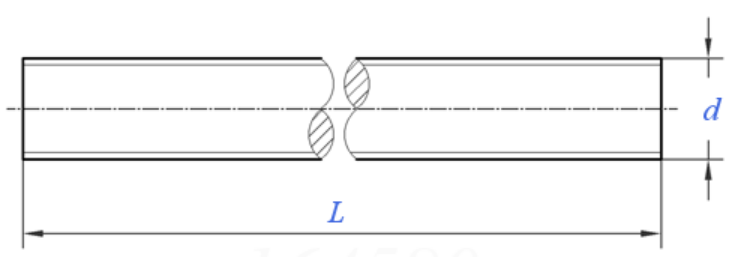

First and foremost, let's consider what exactly stud bolts are. A stud bolt is a cylindrical fastener that typically has threads on both ends, allowing for efficient assembly and disassembly. They are used in conjunction with nuts and are available in various sizes and grades to accommodate different load requirements. The passage from a smaller stud bolt size of 1% (1 inch) to a larger 7/16 inch marks a critical transition in strength, durability, and application.

Understanding the Importance of 1% to 7/16 Stud Bolt Manufacturers

When targeting the 1% to 7/16 inch range, manufacturers face the challenge of producing fasteners that meet specific requirements. Stud bolts in this size range must be capable of withstanding different forms of stress, such as tensile, shear, and fatigue. It's essential that the threaded areas be precisely engineered to ensure proper fit and torque during installation, which directly influences the overall integrity of the assembly.

1 2 stud bolt to 7 16 manufacturers

Additionally, with the rise of technology in manufacturing practices, modern stud bolt manufacturers often utilize advanced machinery and techniques such as CNC machining and automated quality inspection to enhance precision and reduce production times. This not only improves the quality of the final product but also allows manufacturers to offer competitive pricing in the marketplace.

Moreover, stud bolt manufacturers often focus on customization, allowing clients to specify dimensions, coatings, and finishes that meet their unique needs. For example, industries such as oil and gas, construction, and automotive often require specific grades or coatings to ensure performance in harsh environments. Manufacturers who can provide such tailored solutions are indispensable to their clients and are likely to establish long-term partnerships.

Another aspect to consider is the sustainability practices of stud bolt manufacturers. As the world progresses towards more sustainable industrial practices, manufacturers are increasingly focusing on reducing waste, optimizing resource usage, and using eco-friendly materials. Companies that prioritize sustainability not only contribute to environmental protection but also attract clients who value corporate responsibility.

Finally, it is vital for industries utilizing stud bolts to maintain robust relationships with their manufacturers. Open channels of communication can facilitate faster problem-solving, improve delivery times, and allow for better adaptation to market changes and technological advancements.

In conclusion, the transition from 1% to 7/16 inch stud bolt manufacturers embodies the complexity and importance of fastener production. These manufacturers play a critical role in ensuring that industries have access to quality components that meet diverse applications. By prioritizing quality, customization, and sustainable practices, stud bolt manufacturers can better serve their clients and contribute to the efficiency and safety of various industrial sectors.

Latest news

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025

-

Silver Screws Supplier: High-Quality Fasteners for Various Industries

NewsJul.30,2025

-

Top Spike Wheel Nuts Supplier - High Quality & Custom Options Available

NewsJul.29,2025