punch hex bolt supplier

Oct . 09, 2024 13:18 Back to list

punch hex bolt supplier

The Importance of Choosing the Right Punch Hex Bolt Supplier

When it comes to construction, manufacturing, or any assembly work, fasteners play a pivotal role in ensuring structural integrity and operational efficiency. Among the various types of fasteners available, punch hex bolts are particularly popular due to their versatility and strength. However, the performance of these bolts is heavily dependent on the quality provided by the supplier. Thus, choosing the right punch hex bolt supplier should be a strategic decision for any business looking to maintain high standards in its projects.

Understanding Punch Hex Bolts

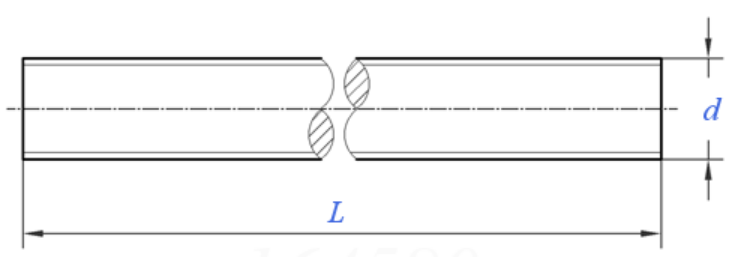

Punch hex bolts, also known as hexagon bolts, are characterized by their hexagonal heads which allow for easy tightening and loosening using standard wrenches. These bolts are typically manufactured from a variety of materials, including steel, stainless steel, and aluminum, depending on the application requirements. Their robust structure makes them suitable for heavy-duty applications, making them an essential component in industries ranging from construction to automotive manufacturing.

Key Factors in Selecting a Supplier

1. Quality Assurance The first and foremost consideration when choosing a punch hex bolt supplier is the quality of the products. Superior quality is non-negotiable, as subpar bolts can lead to catastrophic failures in construction or manufacturing processes. A reliable supplier should adhere to stringent quality control measures and possibly ISO certifications, ensuring that their products meet industry standards.

2. Material Options Different projects require different types of materials. A reputable supplier should offer a wide range of options, including various grades of steel, stainless steel for corrosion resistance, and even specialty alloys for specific applications. This range enables businesses to choose the most suitable bolts for their unique needs.

3. Customizability Often, projects might require custom sizes or finishes. A good supplier should have the capability to provide custom solutions, including bespoke dimensions, coatings, and finishes that align with the specific requirements of a project. This level of service can significantly streamline assembly processes and improve overall efficiency.

punch hex bolt supplier

4. Pricing and Reliability Competitive pricing is important, but it should not come at the expense of quality. The best suppliers strike a balance between cost-effectiveness and quality. Additionally, reliability in terms of delivery times and inventory management is crucial. A supplier that consistently meets deadlines can help businesses maintain their operational efficiencies and avoid costly delays.

5. Customer Service The post-purchase experience is an essential aspect of supplier relationships. A responsive customer service team can help resolve issues quickly, provide technical support, and assist with order inquiries. This level of support fosters a good partnership between businesses and suppliers.

The Long-Term Benefits of Choosing the Right Supplier

Investing time in finding a reliable punch hex bolt supplier can yield long-term benefits. High-quality fasteners can enhance the overall durability and safety of your products, reducing the risks and costs associated with failures and recalls. Furthermore, a solid supplier relationship can lead to collaborative opportunities for new product development and improved manufacturing processes.

Choosing the right punch hex bolt supplier is not just about sourcing materials; it’s about building a reliable partnership that supports your business's growth and success. By prioritizing quality, material diversity, customization options, reliability, and excellent customer service, you position your company to achieve its operational goals while ensuring the safety and satisfaction of your end-users.

Conclusion

In conclusion, the decision on which punch hex bolt supplier to partner with can significantly impact your project’s success. It’s essential to take a comprehensive approach when evaluating potential suppliers. Through careful selection, businesses can benefit from high-quality fasteners that enhance both the operational efficiency and reliability of their products. The right supplier not only provides necessary materials but also becomes an integral part of your manufacturing and assembly processes, paving the way for future innovations and efficiencies.

Latest news

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier & Manufacturer

NewsAug.21,2025

-

Reliable Axle Nuts Supplier | High-Quality Automotive Parts

NewsAug.19,2025

-

Premium Wire Bolts Suppliers | Durable & Reliable Fasteners

NewsAug.18,2025

-

Leading Metric Wood Screw Companies & Manufacturers

NewsAug.17,2025