18 8 stainless steel washers factories

ಸೆಪ್ಟೆಂ . 22, 2024 01:32 Back to list

18 8 stainless steel washers factories

The Significance of 18% 208% Stainless Steel Washers in Manufacturing

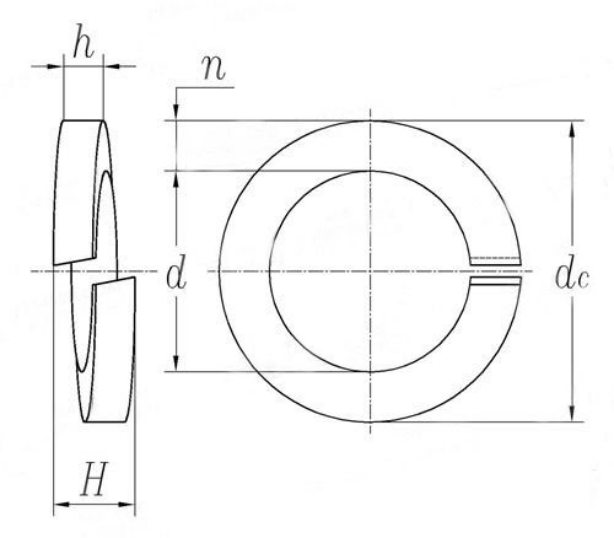

Stainless steel washers are integral components in a wide array of industries, ranging from automotive to aerospace, and even in household applications. Among the various grades of stainless steel, the 18% chromium and 8% nickel grade, commonly referred to as 18/8 stainless steel, is particularly notable for its corrosion resistance and durability. This article explores the significance of 18/8 stainless steel washers, the processes involved in their manufacturing, and the benefits they offer.

Understanding 18/8 Stainless Steel

Stainless steel is defined by its alloy composition, which primarily includes iron, carbon, and a significant percentage of chromium. The 18/8 designation indicates that the alloy contains approximately 18% chromium and 8% nickel. This composition enhances the material's resistance to rust and corrosion, making it perfect for environments that expose components to moisture or chemicals. The nickel content further improves its formability and strength, allowing for the production of washers that can withstand substantial mechanical loads.

Manufacturing Process of 18/8 Stainless Steel Washers

The production of 18/8 stainless steel washers involves several key processes. First, high-quality stainless steel wire is sourced from trusted suppliers, ensuring consistency in the material's properties. Next, the wire is cut to the desired lengths based on washer specifications.

Following this, the cut pieces undergo a stamping process, where they are shaped into washers using high-precision machinery. This stage requires expertise to maintain tight tolerances, which are critical for the washer's performance in various applications. After forming, the washers are often treated through processes such as heat treatment or passivation to further enhance their surface properties and corrosion resistance.

18 8 stainless steel washers factories

The final stage involves quality control, where manufactured washers are subjected to rigorous testing to ensure they meet industry standards

. These tests can include checking for dimensional accuracy, tensile strength, and resistance to corrosion.Applications and Benefits

18/8 stainless steel washers find application in numerous sectors. They are used in the assembly of machinery, automotive components, electronic devices, and even in plumbing fixtures. Their resistance to corrosion makes them an excellent choice for outdoor applications, as they can withstand harsh environmental conditions without deteriorating.

One of the key benefits of using 18/8 stainless steel washers is their longevity. While standard washers may need to be replaced frequently due to rust or damage, stainless steel versions can last significantly longer, leading to reduced maintenance costs and improved reliability in assembled products.

Moreover, 18/8 stainless steel washers are lightweight, which contributes to overall weight reduction in finished products, a crucial factor in industries like aerospace where weight savings translate to better fuel efficiency.

Conclusion

In conclusion, 18/8 stainless steel washers are vital components in modern manufacturing, offering exceptional durability, corrosion resistance, and versatility across various applications. Their manufacturing process ensures high-quality output, making them a favored choice among engineers and manufacturers aiming for the best performance in their products. With ongoing advancements in stainless steel technology, the future of washers and similar components looks promising, supporting industries that continue to evolve.

Latest news

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025

-

Premium Silver Screws Supplier | High-Conductivity Fasteners

NewsJul.31,2025

-

Silver Screws Supplier: High-Quality Fasteners for Various Industries

NewsJul.30,2025

-

Top Spike Wheel Nuts Supplier - High Quality & Custom Options Available

NewsJul.29,2025