High-Strength 12 Point Bolts for Reliable Fastening Solutions

ಸೆಪ್ಟೆಂ . 16, 2024 21:56 Back to list

High-Strength 12 Point Bolts for Reliable Fastening Solutions

Understanding 12-Point Bolts An Overview

In the world of engineering and machinery, bolts play a crucial role in ensuring that components are held together securely and reliably. Among the various types of bolts available, 12-point bolts have gained popularity due to their unique design and significant advantages over other bolt types. This article discusses what 12-point bolts are, their benefits, and their common applications.

What Are 12-Point Bolts?

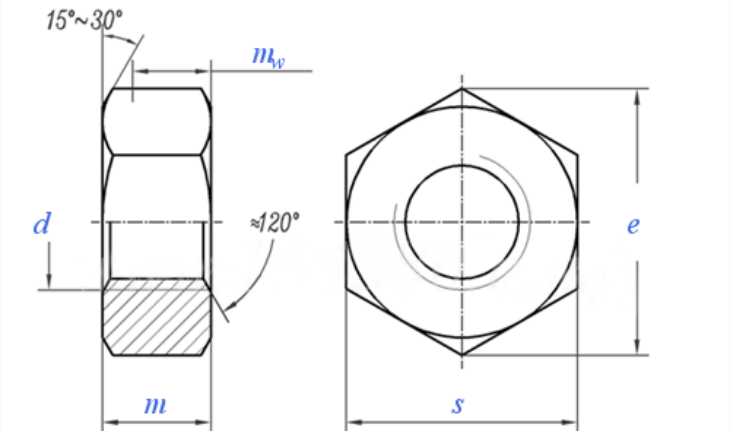

12-point bolts are fasteners characterized by their distinct 12-point head. Unlike traditional hexagonal bolts, which have six sides, the 12-point design allows for greater versatility in wrench engagement. This unique configuration features twelve equally spaced points around the head, permitting a more secure grip and the ability to apply higher torque without stripping. Typically made from high-strength materials, these bolts have threaded shafts that vary in size and length to accommodate different applications.

Advantages of 12-Point Bolts

One of the primary benefits of 12-point bolts is their ease of use in tight spaces. The 12-point socket can be engaged at multiple angles, which means you can work in areas where a traditional wrench would be cumbersome. This flexibility significantly reduces the time needed to tighten or loosen bolts, making them an efficient choice for professionals.

Another advantage is the increased surface contact area. The 12-point design distributes the load more evenly, which minimizes the risk of stripping or damaging the bolt under high-stress applications. This property is particularly beneficial in critical applications, such as automotive and aerospace industries, where the integrity of fastenings is paramount.

12 point bolts

Moreover, because of the ability to use a ratchet at multiple orientations, 12-point bolts can be tightened more effectively than their six-sided counterparts. This characteristic allows for better torque application, leading to more secure fastening and less risk of loosening over time.

Common Applications

12-point bolts are widely utilized in various industries and applications due to their robust characteristics. They are commonly found in automotive engines, where high-torque specifications and compact spaces are prevalent. In aerospace, the reliability of fasteners is crucial, making 12-point bolts an ideal choice for airframe construction and assembly.

Additionally, these bolts are often used in heavy machinery and construction equipment. The ability to withstand high loads and resist stripping makes them suitable for use in environments where durability and performance are non-negotiable.

Conclusion

In summary, 12-point bolts are an excellent choice for professionals looking for reliable, efficient, and versatile fasteners. Their unique design allows for easier engagement in tight spaces, higher torque application, and improved load distribution, making them suitable for high-stress applications across various industries. Whether you're a mechanical engineer, a DIY enthusiast, or a manufacturing professional, understanding the advantages and applications of 12-point bolts can enhance the quality and durability of your projects. As technology continues to evolve, the role of such specialized fasteners will only become more significant in ensuring the stability and reliability of engineered systems.

Latest news

-

Premium Phosphated Drywall Screws Supplier | Durable, Rust-Resistant

NewsAug.27,2025

-

Reliable Wire Bolts Suppliers | Quality Zinc Plated Fasteners

NewsAug.26,2025

-

Wire Bolts Suppliers: Durable & Reliable Fasteners for Every Project

NewsAug.25,2025

-

Premium Cabinet Bolts Supplier | Wholesale & Custom Solutions

NewsAug.24,2025

-

Reliable Axle Nuts Supplier | Quality & Precision Fasteners

NewsAug.23,2025

-

Durable Bolts for Lawn Mower Handle - Top Supplier & Manufacturer

NewsAug.22,2025