oem galvanized flange head bolts

វិច្ឆិកា . 04, 2024 23:52 Back to list

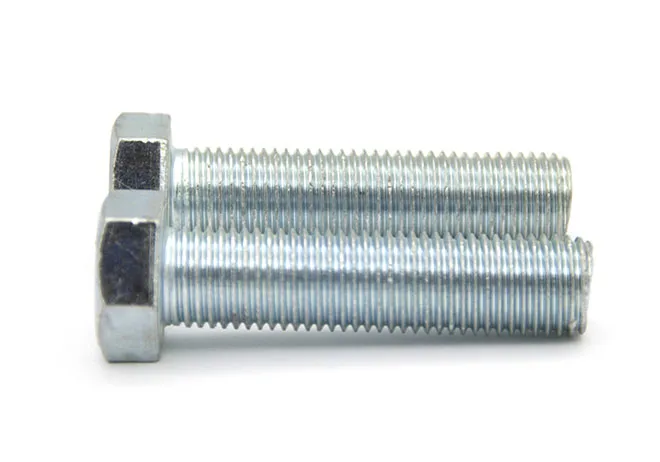

oem galvanized flange head bolts

The Importance of OEM Galvanized Flange Head Bolts in Modern Engineering

In the realms of construction, manufacturing, and engineering, the integrity of connections is instrumental to the overall strength and durability of structures. One critical component that often goes unnoticed yet plays an essential role in ensuring robust assembly is the flange head bolt. This article explores the significance of Original Equipment Manufacturer (OEM) galvanized flange head bolts, their advantages, applications, and considerations for selection.

Understanding Galvanized Flange Head Bolts

Flange head bolts are specialized fasteners characterized by their wide, flat heads, which provide a larger bearing surface. This design allows for an even distribution of load, minimizing the chances of damaging the material being fastened. When these bolts are galvanized, they undergo a process of coating with zinc to protect against corrosion, thereby enhancing their durability, especially in harsh environmental conditions.

The OEM aspect signifies that these bolts are manufactured by companies that produce products tailored to specific requirements set by other manufacturers or industries. This ensures compatibility and reliability within the intended applications.

Why OEM Matters

OEM products, including galvanized flange head bolts, are critically important because they are made to meet exact specifications. Using OEM bolts means that the components will perform as expected, fulfilling safety and operational standards. This reliability is especially essential in industries where failure can lead to catastrophic consequences, such as construction, automotive manufacturing, and aerospace.

Benefits of Galvanization

1. Corrosion Resistance The primary reason for galvanization is to prevent rust and degradation when exposed to moisture and other corrosive elements. This is particularly important for outdoor applications or in environments with high humidity, chemicals, or salt.

2. Longevity Galvanized flange head bolts typically outlast their non-galvanized counterparts. The protective layer allows structures to maintain their integrity over longer periods, reducing the need for frequent replacements and maintenance.

3. Cost-Effectiveness While OEM galvanized flange head bolts may have a higher initial cost than standard bolts, their longevity and resilience can lead to significant cost savings in the long run due to reduced maintenance and replacement expenses.

oem galvanized flange head bolts

Applications in Various Industries

Galvanized flange head bolts are widely utilized across various sectors. Some common applications include

- Construction Used in connecting structural elements such as beams, columns, and trusses, ensuring stability and safety in buildings and bridges. - Automotive Integral in assembling vehicle components where strength and durability are paramount. - Manufacturing Employed in machinery and equipment where precise fastening is required for operational efficiency. - Aerospace Critical in aircraft assembly, where performance and safety cannot be compromised.

Key Considerations When Choosing OEM Galvanized Flange Head Bolts

When selecting the right flange head bolts, several factors should be considered

1. Material Specifications Ensure the bolts meet the specific material requirements necessary for the application. This includes checking the grade of steel used and the thickness of the galvanization.

2. Load Requirements Assess the load and torque specifications to select bolts that can handle the expected forces without failing.

3. Environmental Conditions Consider the environmental factors to which the bolts will be exposed, such as moisture levels, temperature variations, and presence of chemicals.

4. Standards and Compliance Verify that the bolts comply with relevant industry standards (e.g., ASTM, ISO) to ensure safety and reliability.

5. Supplier Credentials Choose reputable suppliers with a strong track record in providing OEM components, ensuring both quality and service.

Conclusion

In conclusion, OEM galvanized flange head bolts are indispensable components in contemporary engineering and construction. Their unique design, coupled with the protective benefits of galvanization, makes them a superior choice for applications requiring reliability and strength. As industries continue to evolve, the demand for high-quality fastening solutions will only increase, underscoring the importance of selecting the right components for safe and effective assembly. By choosing OEM products, businesses can achieve the best possible results in their projects, ensuring longevity and durability in their structures and machinery.

Latest news

-

Premium Wire Bolts Suppliers | High-Quality Bolts

NewsAug.05,2025

-

Trusted Wire Bolts Suppliers - Durable & Reliable Solutions

NewsAug.04,2025

-

Wire Bolts Company | Premium Industrial Fasteners

NewsAug.03,2025

-

Top Wire Bolts Suppliers | AI-Optimized Fast Delivery

NewsAug.02,2025

-

Top Metric Wood Screw Companies | Durable & Reliable

NewsAug.01,2025

-

Premium Lawn Mower Handle Bolts Supplier | Fast Delivery

NewsJul.31,2025