camber adjustment bolts

មករា . 28, 2025 00:52 Back to list

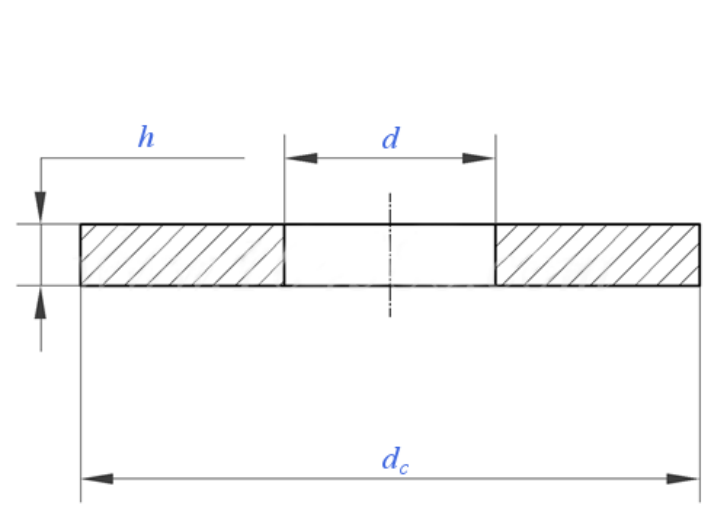

camber adjustment bolts

Camber adjustment bolts, often heralded as the unsung heroes of the automotive world, serve as an indispensable component for ensuring the precise alignment of a vehicle's wheels. Their subtle yet profound role in vehicle performance and safety is matched only by the expertise required to utilize them effectively. This article delves into the nuances of camber adjustment bolts, leaving readers with a solid grounding in their significance and application.

Moreover, trustworthiness in choosing the right component can be as crucial as the installation itself. It starts with sourcing products from respected manufacturers known for rigorous quality control standards and reliable performance records. Opt for bolts that have been thoroughly tested under various conditions to ensure they meet the highest safety and performance benchmarks. Authoritativeness in the realm of camber adjustment bolts also extends to installation. Entrust this job to skilled technicians with a track record of aligning and adjusting high-performance vehicles, as they bring a wealth of experience and nuanced understanding to the task. It’s usually during alignment sessions that the need for camber adjustment bolts becomes apparent, making regular wheel alignment checks a critical aspect of vehicle maintenance. Ultimately, investing in quality camber adjustment bolts and employing them under expert hands not only preserves vehicle integrity but enhances its overall performance. Whether aiming for smoother everyday driving or preparing a vehicle for the demands of racing circuits, these small yet impactful components are fundamental in achieving desired results. In summary, camber adjustment bolts are far from mere mechanical components; they are pivotal to ensuring balanced and proficient vehicular performance. By drawing on professional expertise, prioritizing quality, and understanding the fundamental principles of alignment, you assure yourself of a driving experience both safe and exhilarating.

Moreover, trustworthiness in choosing the right component can be as crucial as the installation itself. It starts with sourcing products from respected manufacturers known for rigorous quality control standards and reliable performance records. Opt for bolts that have been thoroughly tested under various conditions to ensure they meet the highest safety and performance benchmarks. Authoritativeness in the realm of camber adjustment bolts also extends to installation. Entrust this job to skilled technicians with a track record of aligning and adjusting high-performance vehicles, as they bring a wealth of experience and nuanced understanding to the task. It’s usually during alignment sessions that the need for camber adjustment bolts becomes apparent, making regular wheel alignment checks a critical aspect of vehicle maintenance. Ultimately, investing in quality camber adjustment bolts and employing them under expert hands not only preserves vehicle integrity but enhances its overall performance. Whether aiming for smoother everyday driving or preparing a vehicle for the demands of racing circuits, these small yet impactful components are fundamental in achieving desired results. In summary, camber adjustment bolts are far from mere mechanical components; they are pivotal to ensuring balanced and proficient vehicular performance. By drawing on professional expertise, prioritizing quality, and understanding the fundamental principles of alignment, you assure yourself of a driving experience both safe and exhilarating.

Latest news

-

Top Wire Bolts Suppliers - Quality & Durable Fasteners

NewsAug.15,2025

-

Trusted Wire Bolts Company | Quality Fasteners Supplier

NewsAug.14,2025

-

Reliable Wire Bolts Suppliers & Manufacturers for Global Needs

NewsAug.13,2025

-

High-Quality Bolts for Lawn Mower Handle Supplier

NewsAug.12,2025

-

Leading Phosphated Drywall Screws Supplier | Bulk & Custom Orders

NewsAug.11,2025

-

Top Wire Bolts Company: Manufacturers, Exporters & Suppliers

NewsAug.10,2025