Optimal Cylinder Head for Stud Bolt Installation and Performance Analysis

ធ្នូ . 14, 2024 20:33 Back to list

Optimal Cylinder Head for Stud Bolt Installation and Performance Analysis

The Importance of Selecting the Best Head to Intake Stud Bolt A Guide for Performance Enthusiasts

When it comes to high-performance engine builds, the choice of components significantly impacts overall efficiency, reliability, and power output. Among these components, head to intake stud bolts may not receive the same attention as camshafts or turbochargers, but they play a crucial role in ensuring that your engine runs smoothly and reliably. This article aims to guide enthusiasts in understanding the importance of selecting the best head to intake stud bolts and how they contribute to engine performance.

Understanding Head to Intake Stud Bolts

Head to intake stud bolts are critical fasteners that secure the intake manifold to the cylinder head of an engine. These bolts must withstand not only the tension from the manifold but also the dynamic forces generated by the engine during operation. Given the environment in which they function—high temperatures, pressures, and vibrations—choosing the right materials and designs for these bolts is essential to ensure long-term durability and performance.

Materials Matter

The material of the bolts is one of the most important factors to consider. Most factory-styled bolts are made from standard steel, which offers adequate strength for everyday applications, but high-performance applications demand better options. Upgrading to bolts made from materials like stainless steel, titanium, or even aerospace-grade alloys can provide enhanced strength and performance

1. Stainless Steel Offers excellent corrosion resistance and durability, making it a preferred choice for many enthusiasts. Stainless steel bolts can withstand the harsh environments typical of high-performance engines.

2. Titanium While titanium bolts can be more expensive, they offer a significant strength-to-weight ratio. This makes them ideal for racing applications where every ounce counts.

3. Aerospace-Grade Alloys These provide the ultimate in strength and durability, suitable for extreme power applications. They can handle the immense stresses of racing engines while minimizing the risk of failure.

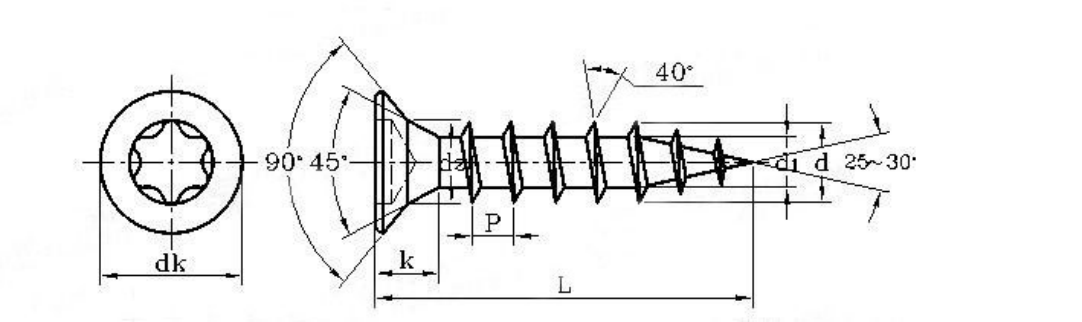

Thread Design and Length

best head to intake stud bolt

The thread design and length of the stud bolts are also critical considerations. Proper thread engagement is essential for maintaining the integrity of the connection between the intake manifold and the cylinder head. Longer studs may allow for better clamping force, reducing the risk of warping and failure, especially under high boost or extreme conditions.

Additionally, consider the pitch of the threads. Fine-thread studs typically offer better tension characteristics, which can be beneficial in high-performance scenarios. However, they may also require more precision during installation to prevent cross-threading.

Installation Techniques

Even the best head to intake stud bolts can fail if improperly installed

. It’s crucial to follow best practices when installing these bolts to ensure they achieve optimal clamping force without overtightening, which could lead to stripping or breaking.1. Torque Specifications Always adhere to the manufacturer's torque specifications. Using a calibrated torque wrench will help prevent over-tightening, ensuring that the bolts are secured adequately without being compromised.

2. Sequential Torquing Applying torque in a sequence—similar to tightening a wheel lug—helps disperse the force evenly across the surface, reducing the risk of warping.

3. Lubrication Consider using a lubricant on the threads. This can help in achieving consistent torque readings and ensure the threads do not gall during installation.

Wrapping It Up

In the realm of performance tuning, the details matter—and selecting the best head to intake stud bolts is no exception. By understanding the materials, thread design, and installation techniques, enthusiasts can ensure that their engine's intake manifold remains securely fastened, providing reliable performance under load and during high-speed operation. Investing in high-quality bolts may seem like a minor consideration in the grand scheme of engine building, but it pays dividends in performance reliability and longevity.

Whether you're a seasoned racer or an enthusiastic weekend mechanic, never underestimate the significance of the components that hold your powertrain together. The right head to intake stud bolts might just be the key to unlocking your engine's full potential, allowing you to push the limits safely and effectively.

Latest news

-

High-Quality Panel Stud Bolt Reliable Panel Stud Bolt Factory & Suppliers

NewsJul.08,2025

-

High-Precision Fine Thread Locknuts Manufacturer & Supplier Custom Solutions

NewsJul.08,2025

-

PH Imperial Stud Bolt – High Strength Fasteners from Leading Supplier & Factory

NewsJul.07,2025

-

High-Quality Allen Wrench Bolts Leading Factory, Company & Suppliers

NewsJul.07,2025

-

Wholesale Ball Stud Bolt - High Quality Supplier & Factory Price Reliable Wholesale Ball Stud Bolt Company

NewsJul.06,2025

-

High-Strength Alloy Bolts Manufacturer & Supplier Quality Alloy Fasteners Factory

NewsJul.06,2025